Schroeder Industries introduces the Schroeder Varnish Elimination Unit (VEU). With the scheduled (and often times unscheduled) dollar value of replacement hydraulic parts and the pressure to maintain a 100% planned up-time schedule, most operators are shocked to learn that the level of operational quality lies solely in the cleanliness of their … [Read more...] about Varnish Elimination Unit removes sludge from hydraulic fluid

Fluids

Universal Tractor Hydraulic Fluids ensure smooth, efficient operation

Champion Oil understands the operational importance of specific hydraulic systems and applications. Universal Tractor Hydraulic Fluids (UTHF) are commonly used in agriculture as well as in many types of mobile and off-road equipment including excavators and loaders. UTHF improve the productivity of farm tractors by protecting the tractor parts. … [Read more...] about Universal Tractor Hydraulic Fluids ensure smooth, efficient operation

Flat-plate heat exchangers enable cool, reliable mining

Mining machines and equipment face tough and unforgiving operating conditions, and the hydraulic systems they rely on have to stand up to the abuse and, in some cases, extreme heat. Facing a unique combination of challenges, a mineral-processing OEM approached GS Global Resources, Mukwonago, Wisc., for engineering assistance while designing a … [Read more...] about Flat-plate heat exchangers enable cool, reliable mining

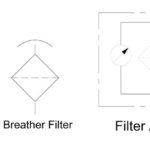

Hydraulic Symbology 304 – conditioning and monitoring

By Josh Cosford, Contributing Editor The use of hydraulic symbols must be comprehensive in your efforts to detail the workings of a complete hydraulic system. Hydraulic machines consist of more than pumps, valves and actuators, of course, even though they are often the stars of the show. Those stars would quickly fall into the other side of fame … [Read more...] about Hydraulic Symbology 304 – conditioning and monitoring

Des-Case continues summer webinar series

Des-Case has announced its will continue its online training series, with a new Summer Playlist Series: Thursdays at 11:00 am CST. The following topics will be covered as the company works to educate users on fluids and maintenance. June 25, 2020: What’s Oil Got to Do With It? When used properly, oil analysis is an invaluable insight into … [Read more...] about Des-Case continues summer webinar series

Filler and tank breathers for fixed and mobile hydraulic applications

Ohio Fabricators Company (OFCO) has announced its new line of filler and tank breathers for a wide variety of fixed and mobile hydraulic applications. OFCO breathers are available in a bayonet style, threaded style and as pressure caps. Each style can be manufactured with a black e-coat, chrome or zinc plated cap. All OFCO breathers are … [Read more...] about Filler and tank breathers for fixed and mobile hydraulic applications

New oil line indicator is ATEX compliant for hydraulic systems components

The ELESA ATEX line has been recently enlarged with the new HFTX-EX oil level indicator in transparent technopolymer with an anodized aluminum star-shaped contrast screen. It is characterized by a magnifying lens with a particular shape to increase and improve visibility, even from side positions. Other products in the ELESA ATEX line include … [Read more...] about New oil line indicator is ATEX compliant for hydraulic systems components

Oil property sensor measures oil quality, condition and contaminants

With companies searching for ways to optimize and ensure longer lifetimes for equipment, reliable and accurate, oil condition monitoring sensors are important. To meet this need, the FPS2800 oil property sensor from TE Connectivity is optimized for fluid condition monitoring in applications from industrial machinery and compressors to off-road … [Read more...] about Oil property sensor measures oil quality, condition and contaminants

Schroeder Industries unveils fluid cleanliness training program

Schroeder Industries is unveiling a new training program for OEM’s and MRO operations called “Schroeder’s Fast Fifteen,” which provides targeted fluid cleanliness concepts in 15 minutes. The company is using its 70 years of expertise to build out this brand-new training concept. With most corporations vying for users' attention during this time, … [Read more...] about Schroeder Industries unveils fluid cleanliness training program

Top 5 Spring maintenance tasks for fluid power systems

By Josh Cosford, Contributing Editor It was 20° here in Burlington, Ontario yesterday. No, not 20° Fahrenheit, but 20° Celsius … equating to something like 68° F. Nevertheless, it was warm enough to have our entire family outside playing basketball in the driveway. Because of the weather and the lack of human gatherings, I’m seeing a number of … [Read more...] about Top 5 Spring maintenance tasks for fluid power systems