By Josh Cosford, Contributing Editor

All hydraulic fluid is designed to transmit fluid power energy through a system, and for the most part, they do the job the same way. But that doesn’t mean all oil is the same. In fact, there are five common types of hydraulic fluid, each with its benefits and downsides whose use depends on the application best suited for them.

Anti-Wear hydraulic fluid enjoys the comfortable throne atop the hydraulic fluid kingdom. Anti-wear oil derives from petroleum oil, offering excellent lubricity, superior corrosion protection and great oxidation resistance. AW oil generally offers a good viscosity index and heat transfer as well but fairs poorly in flame-resistant applications, being quite flammable.

Anti-Wear hydraulic fluid enjoys the comfortable throne atop the hydraulic fluid kingdom. Anti-wear oil derives from petroleum oil, offering excellent lubricity, superior corrosion protection and great oxidation resistance. AW oil generally offers a good viscosity index and heat transfer as well but fairs poorly in flame-resistant applications, being quite flammable.

AW oil is the jack of all trades product that suits the majority of hydraulic systems and machinery in a wide range of temperature applications. Additives easily improve the base oil to increase performance, and AW oil is offered in a wide range of viscosity offerings.

Biodegradable hydraulic fluid gets its base stock from renewable and natural oil sources, such as seed sources like soy or canola. These fluids benefit not only from their renewable source but their safer impact on the local environment should they spill or leak. Bio oils also offer excellent lubricity and corrosion protection, but their viscosity is more likely to change with temperature. Granted, the overall effective temperature range of most bio-oil is very good.

Bio-oil makes its home in any hydraulic application where the possibility of contamination exists in a sensitive environment. Forestry machinery does well to be offered with bio-oil, which does not contaminate soil after a leak. Food-safe applications do well to take advantage of the fully ingestible nature of bio-oil since cross-contamination results in a less daunting cleanup effort after a spill.

Synthetic fluid offers good performance across the board in most categories; viscosity index, lubricity, oxidative stability, corrosion protection and thermal transfer capacity. Depending on the base oil, it may also offer fair fire resistance.

With a quality additive package, a synthetic blend offers the best choice for most hydraulic fluid requirements. Expect to have excellent all-weather performance, superior lubrication and corrosion protection.

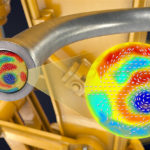

Phosphate Ester was created as a synthetic form of fire-resistant fluid, used primarily in steel mills or aircraft hydraulics. So if your hose springs a leak, the last thing you need is a flame thrower should a spark intercept the jet of oil. Phosphate Ester also enjoys good overall oxidative stability, corrosion protection and thermal transfer properties. However, its viscosity tends to be more affected by temperature than other fluids.

Water Glycol offers some excellent properties as a hydraulic fluid; mainly being water, it has an outstanding viscosity index, fire resistance and thermal transfer capacity. However, as you would imagine, it’s merely okay regarding lubricity and oxidation while being the poorest of the top five with corrosion resistance.

Water glycol has replaced phosphate ester in many steel mill applications, being a much less aggressive fluid on seals, paint and personnel. However, it tends to be a high maintenance fluid, requiring frequent testing to confirm its specific gravity suites specification. Typically, the ratio is 60:40 or 65:35 glycol to water, and as you imagine, the water evaporates over time and requires replenishing.

Leave a Reply