By Josh Cosford, Contributing Editor

Aeration is the introduction of air bubbles within a liquid by passing through or across open air. Aeration most often occurs in hydraulic systems when oil returns to the tank above the oil level in the reservoir, entraining bubbles as it splashes into the tank.

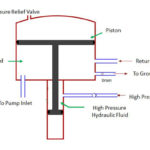

The primary worry with aeration is the damaging effect on hydraulic pumps. As a free bubble makes its way to the pressure side of a pump, it implodes under the compressive force of the hydraulic fluid and creates a super-heated jet that damages swash plates, pistons, gears, or vanes (depending on the pump). You’ll likely recall this effect from another brutal occurrence called cavitation, where instead of bubbles joining from free air, they spontaneously form under excessive suction line vacuum.

In some cases, aeration proliferates the entire hydraulic system. For example, poorly maintained hydraulic oil is more susceptible to aeration, as the viscosity-raising effects of oxidation and sludge leave the oil more likely to retain bubbles. In addition, with poor return line conditions causing aeration, the hydraulic system can sometimes not expel them as quickly as they arrive, causing the hydraulic fluid to turn to foam essentially.

If you’ve ever wondered what would happen in a hydraulic/pneumatic hybrid system, then it definitely involves foamy oil. When oil is foamy, it has compressibility like air. The oil bubbles entrained in the hydraulic fluid compress, decreasing the bulk modulus of the oil. The pressure capacity of the oil remains high as standard hydraulic oil, but the motion of the hydraulic actuators may be unpredictable. Actuators may move in jumps and spurts as air bubbles compress and then expand, almost like a pneumatic cylinder with severe chattering issues.

Foamy oil accelerates the oxidation of the oil but through inferior heat transfer and higher exposure to oxygen. Because air transfers thermal energy more poorly than liquid, the hydraulic system is likely to run hotter, which in turn succumbs to higher oxidation while exposed to more free oxygen in the air bubbles.

Air makes a poor lubricant compared to oil, so whenever air bubbles displace hydraulic fluid, your components experience accelerated wear. More metal-to-metal contact occurs with aerated oil, including pumps and motors, which experience the most damage under these conditions. In addition, higher pressure exacerbates wear as the force generated is higher across the metal surfaces, such as the piston slippers against the wear plate of a piston pump or the vanes against the cam ring of a vane pump.

The best way to solve the problem of aeration is to prevent it with intelligent power unit design, ensuring all lines exit below the surface of the oil and offering a reservoir large enough to provide sufficient time for bubbles to release back into the air. Suppose your aeration problem occurs from an unknown culprit. In that case, your last resort might be to pour anti-foaming additives in with your fluid that resists aeration while improving the capacity to release bubbles.

Leave a Reply