It’s common knowledge that particulate contamination is unwanted in hydraulic systems. Contamination in hydraulic oil can damage mobile and industrial machinery. Of as much concern should be water in oil, as it too can lead to component failure.

Water in hydraulic fluid can be seen as free, dissolved or emulsified and can reduce hydraulic fluid lubricity, cause pitting against metal surfaces, degrade additives and accelerate oil aging. As a result, it is necessary to mitigate the presence of water in hydraulic systems. But before you can do that, first you must understand what types of water exist in a hydraulic system.

Free water is easily identifiable, as it can be visually seen if you pull oil from a system. This water separates clearly from the oil and can easily be decanted out of the reservoir because the specific gravity of most oils is less than 1.00.

Emulsified water is that which has blended with the oil so it can’t be decanted. Think of a bottle of salad dressing, in which the oil and vinegar/water are mixed upon shaking.

Dissolved water is the most difficult to identify and remove. This usually forms as the oil temperature increases — just as it is easier to dissolve salt in boiling water, so it is easier for hydraulic fluid to absorb water in hotter temperatures.

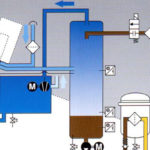

For emulsified or dissolved water, vacuum dehydration is the best option. These online or offline machines use heat (within a critical range as too high a heat will break down the oil) and vacuum technologies to remove water from oil. These systems will also remove particulates in the final stage.

Leave a Reply