Contributed by James Czegledi, Engineering manager, Peninsular Cylinders

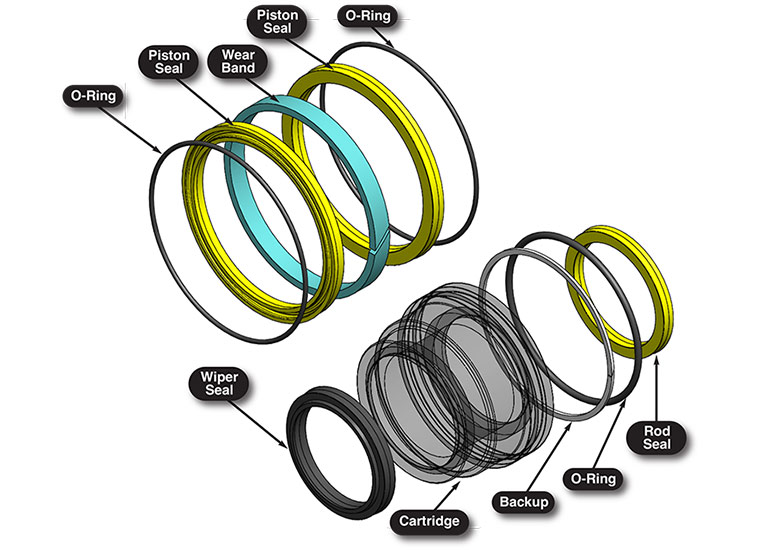

It can happen at anytime, most often without notice — your cylinder has failed. More often than not the failure can be attributed to a seal or seals used inside of the cylinder. Let’s take a look at the types of seals typically found inside a hydraulic cylinder.

It can happen at anytime, most often without notice — your cylinder has failed. More often than not the failure can be attributed to a seal or seals used inside of the cylinder. Let’s take a look at the types of seals typically found inside a hydraulic cylinder.

- Piston seals — Used to keep oil onto the work side of the piston.

- Rod seals — The most important seal type used to prevent leakage from inside the cylinder to the outside.

- Buffer seals — Absorb changes in pressure when working with high-load conditions. Typically placed in front of rod seal.

- Wiper seals — Prevent outside contaminants from entering the cylinder assembly/system.

- Wear bands — Guides the piston and rod of a hydraulic cylinder and absorbs transverse forces. Also, prevents metal on metal contact.

The most common reasons for seal failure and some possible causes include the following:

- Hardening — Too much heat being generated from a high-speed application or environmental conditions surrounding the cylinder. This can be avoided by using the proper materials for high-temperatures, or using shielding, insulation and cylinder cooling.

- Wear — Excessive wear due to not enough lubrication. Excessive lateral load results in worn bearing/wear ring.

- Scarring/Contamination — It can be easy for contaminates such as shop debris, wood splinters or improperly filtered oil to impact the cylinder operation. Once contaminates are inside the cylinder, it can lead to scars or imperfections on the rod or bore that will scar the seals.

- Fracture — Resulting from excessive back pressure, high pressure spikes/shocks and a loss of material/fluid over time.

- Improper Installation — Not using the proper tools to install seals can lead to damage and leaks. Most manufacturers offer installation tips, including surface specs and groove dimensions. In addition, inspecting tools for nicks or cuts can prevent seal damage. Finally, avoid twisting seals during installation.

The end user is most concerned with the cylinder being able to handle the required payload at a certain speed. They are also focused on repeatability, whereas an engineer would requires the pertinent information disclosed to ensure the design is the best it can be.

For instance, while there is an ideal working pressure, there can be spikes throughout the system that occur when a direction change happens. Additional or different seal designs can be implemented to control and handle the variations in pressure.

This application data is critical when determining the seal types. Most manufacturers have this data readily available. An electronic application data sheet from Peninsular is used to determine a recommended cylinder design. The data sheet collects such information as working pressure, fluid pressure, temperature range, fluid type and more.

General maintenance should also be conducted. For example, having a seal kit replacement on hand can extend the overall life of the cylinder. In some circumstances it may also make sense to have a backup or spare cylinder available to avoid costly downtime.

Using the aforementioned application data and close relationships with design engineers can ensure the right cylinder and seal package for all demanding applications.

Peninsular Cylinder Co.

peninsularcylinders.com

Leave a Reply