By Josh Cosford, Contributing Editor

Static seals are used in hydraulic applications where two mating surfaces or edges require positive sealing. A static seal, by definition, is one that remains stationary and subjected to no movement and its related friction. A static seal may be exposed to hydraulic pressure on both sides or be exposed to hydraulic pressure on one end and air on the other.

Most often in hydraulics, static seals are used to seal a body, flange or head to another stationary tube, cap or other components. One example is the rear cover of a piston pump that must seal against the pump housing and does so with a gasket or O-Ring. The seal must only contain low-pressure case oil and prevent it from leaking unintentionally from the pump.

Most often in hydraulics, static seals are used to seal a body, flange or head to another stationary tube, cap or other components. One example is the rear cover of a piston pump that must seal against the pump housing and does so with a gasket or O-Ring. The seal must only contain low-pressure case oil and prevent it from leaking unintentionally from the pump.

A similar example exposed to high pressure is the flange cover of a gear pump. The case of a gear pump which contains the spur gears creating pressure must be able to withstand full pump pressure, and as such, the static seal must be rugged enough to avoid extrusion and leakage.

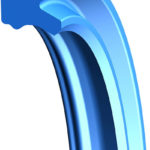

In a hydraulic cylinder, static seals are used to seal the barrel to the head and cap in tie-rod cylinders, or perhaps the head or gland of a welded cylinder. Once again, these static seals must prevent internal pressure from escaping. Static seals used to seal a tube in tie-rod cylinders are especially prone to failure if extrusion gaps are too large, allowing tie-rod stretch to loosen gaps and provide a path for extrusion.

In cartridge valve applications, the “ways” describe the ports of a valve. A 5-way valve has five ports, and in a cartridge valve cavity, each port must be positively sealed from each other, and in most cased bi-directionally. The spool itself inside the cartridge valve seals through tight clearances and full film lubrication, but without the static seals between each way, internal leakage would prevent the valve from functioning properly or even at all. As well, even the top of the cartridge valve must be sealed inside the cavity to prevent external leakage.

Static seals are often just an O-Ring, but when extreme pressure is possible, harder rubber or plastic backup rings will sit behind the O-Ring to support it as it’s exposed to pressure. In places where extrusion gaps are minimal, such as a pump housing, backup rings are rare. However, most cartridge valves will use backup rings to support O-Rings in either direction, using essentially three components to achieve a static seal.

Leave a Reply