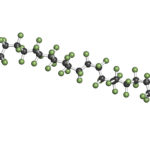

NBR is an acronym for nitrile butadiene rubber but goes by many other names, such as nitrile or buna. NBR is a synthetic rubber compound made from acrylonitrile and butadiene. Buna is renowned for its natural resistance to oils, fuels, water and many other chemicals.

You may use NBR for most hydraulic applications, especially those within the typical operating parameters of a basic hydraulic system. Anti-wear mineral oil, water-glycol and high water-based fluids are suitable for combining with NBR seals.

You may use NBR for most hydraulic applications, especially those within the typical operating parameters of a basic hydraulic system. Anti-wear mineral oil, water-glycol and high water-based fluids are suitable for combining with NBR seals.

NBR is stable over a wide thermal range of –40° to 226°F (–40° to 108°C), which is well within the usable range of any hydraulic system. Furthermore, Buna is reliable even in the outer reaches of the above temperature range and even in the presence of contamination and chemicals.

Buna is a great all-around performer in the fluid power world but doesn’t operate well in the extreme ends of the performance spectrum. If your machine operates in ambient conditions colder than –40°F (–40°C) and hotter than 226°F (108°C), you may want to select a different polymer.

Moreover, some fluids are not compatible with NBR, such as polyol esters. Also, some chemical environments are not suitable, such as those with ammonia vapor that may contaminate the oil.

Although Buna is stable down to –40°F (–40°), it doesn’t mean it’s suitable to operate when ambient cold is that extreme. The seals will shrink and reduce their ability to seal, especially under pressure. Realistically, consider the lower range of NBR seals in hydraulics to be –20°F (–29°C).

That being said, some manufacturers offer specialty compounds rated for as low as –65°F (–54°C), such as military-grade NBR. If you have a low-temperature application, reach out to your preferred seal supplier.

Buna works great to seal both piston and rod seals in a cylinder. However, they have their limitations. An NBR piston t-seal offers very low leakage even at high pressure. However, the NBR compound counts upon an interference fit between the piston and barrel, and that fitment results in high friction. Expect not much more than a few feet/second maximum velocity for a buna piston seal.

Very interesting and informative article on NBR/Buna rubber seals..