By Josh Cosford, Contributing Editor

For any seal to function well in a fluid power application, it must resist the extreme forces attempting to squeeze the material through even the smallest gap like so much Playdoh. The gaps available to a seal to squeeze through are called extrusion gaps.

To understand the extrusion gap, you must first understand the primary role of a seal, which is to keep separate two areas of differential pressure, fluid or medium. For the sake of this discussion, hydraulic seals keep pressurized hydraulic fluid where it best serves our purpose – somewhere it can transfer energy with as little lost to leakage as possible.

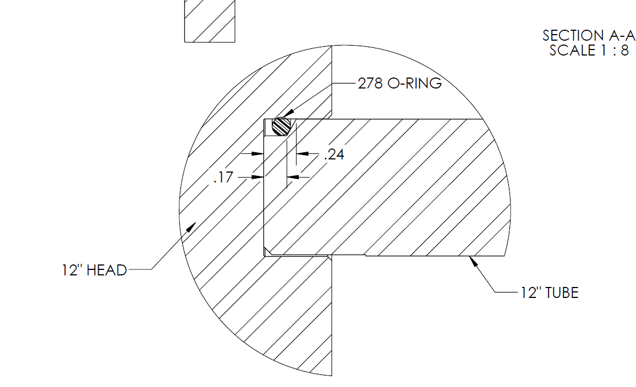

Any two separate areas requiring a seal also include a gap where two individual components meet, such as the end-seal on a hydraulic cylinder that seals the tube ID from the air outside the cylinder. Image 1 shows an end-seal design that may be subjected to extrusion as tie rod stretch opens the seal gap. No matter how well-engineered, machined and assembled, no two separate components can be so close to each other as to prevent leakage between those two components at high pressure. Thus, seals literally fill the gap between parts.

The gaps in and around the seal cavity also offer a dangerous opportunity. Those gaps offer a path for the seal to take when exposed to pressure of sufficient force. Many soft seal compounds, such as Buna Nitrile, act almost like putty when exposed to extreme pressure. That putty has the opportunity to squeeze through the extrusion gap.

Seal manufacturers publish cavity dimensions and tolerances that best suit the seal construction and polymer. It’s essential to design within these published dimensions to prevent the possibility of extrusion. A small enough extrusion gap is no gap at all, making the seal effective against even the most extreme pressure cycles. It simply takes intelligent engineering and precision manufacturing.

Sometimes even small extrusion gaps may eventually wear away at seals, especially when movement is involved. For example, a piston seal under high pressure, even with tight gaps, still has potential for extrusion. As pressure softens the seal, the added friction of movement can pull the seal out through the extrusion gap, albeit very slowly. This slow process of extrusion is sometimes referred to as “nibbling.” Image 2 shows an example of a seal extruded over some time.

All threats of danger aside, hydraulic component manufacturers are well aware of the potential for seal extrusion. Pumps, valves, and cylinders are all manufactured within tight tolerances of the appropriate dimensions, and extrusion is rare for off-the-shelf hydraulics. The concern comes when rookie engineers or designers do not adhere to the catalog specifications. Be sure to select a seal appropriate for the application and create the seal cavity best suiting that seal.

Leave a Reply