By Josh Cosford, Contributing Editor

Most hydraulic fluid is oil-based, so we cannot forget the adage that oil and water do not mix well. However, when it comes to the hydraulic oil transferring energy around your hydraulic system, much more is at stake. Whether free or in saturation, the potential harm from water is more detrimental than merely pooling at the bottom of your reservoir.

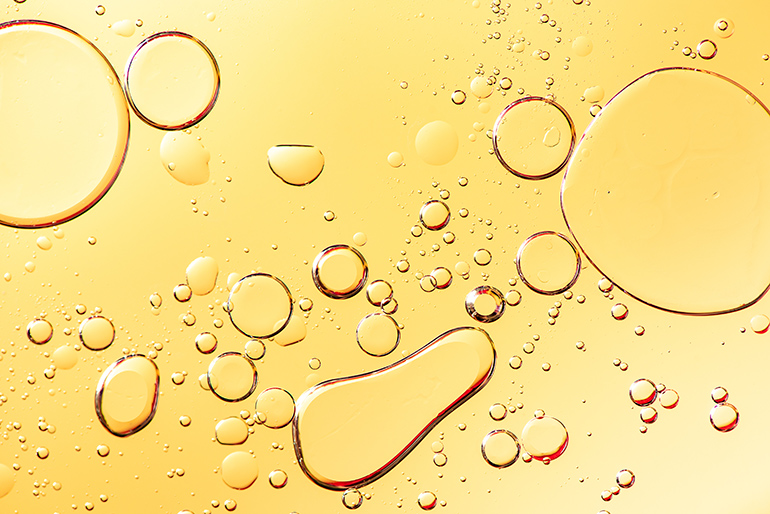

Nearly every beneficial property of hydraulic oil is reduced or compromised when water contaminates it. Water will contaminate hydraulic oil in two ways; as either free water or saturated water. Free water is what exists as pockets or bubbles of separate water droplets. Saturated water is the dissolved kind — sharing space within the oil itself. Hydraulic oil can be humid just like air, and it’s nearly impossible to remove all humidity from oil, but you do want to keep it to a minimum.

Relative water humidity less than 99% will keep the water entirely dissolved, but temperature differences will result in free water “raining” out of the fluid. Even if you could maintain water saturation just shy of 100%, the excess water will give the oil a telltale milky appearance. Milky oil is terrible under any circumstance.

Water-contaminated oil reduces the lubricity of the hydraulic oil. Oil’s viscosity and shear-resistance provides a film barrier between two wear surfaces. Water contamination reduces both the viscosity and shear resistance, allowing metal to metal contact to occur. Although water-saturated oil may still provide full film lubrication under pressure, it loses that protection in areas of little pressure.

A lesser-known fact of “wet” oil is the accelerated oxidation rate. Oil oxidation rate increases with heat, which is a common occurrence of many hydraulic systems. The increased oxidation results in the fracturing of oil molecules, which in turn creates varnish as the severed atoms stick to each other and additives in the oil. (The oxidation being discussed here is of the oil itself, not the metal components exposed to it.)

It’s easy to connect oxidation with metal components’ rusting, which also occurs inside water-contaminated hydraulic systems. Water-based hydraulic fluids employ rust-inhibiting additives, but because hydraulic oil is inherently rust preventive, highly saturated oil provides little such protection. The case is exacerbated when free water pools in steel or iron locations, especially during downtime. It goes without saying; you must avoid excessive water contamination at all costs.

Outstanding article. So much information written in a small space.

I remember seeing the affect water has on additives first-hand in the field with large wheel loaders in an automobile scrap yard.

A mechanic removed a spin-on filter cartridge from a hydraulic system and asked what the sticky substance was that resembled,”Silly String”.

That was what used to be a R&O additive, prematurely used up by the excess water content I told him.

Was I right?