By Josh Cosford, Contributing Editor

Hydraulic oil contamination may cause significant damage to hydraulic systems and components, leading to reduced performance and productivity and increased maintenance and repair costs. Therefore, it’s crucial that you identify the symptoms of hydraulic oil contamination to prevent further damage and ensure optimal hydraulic system operation. Regular readers know how much I preach the importance of hydraulic fluid cleanliness programs, including mitigating contamination. We all know contamination causes excessive and premature wear, but what are the less common contamination symptoms?

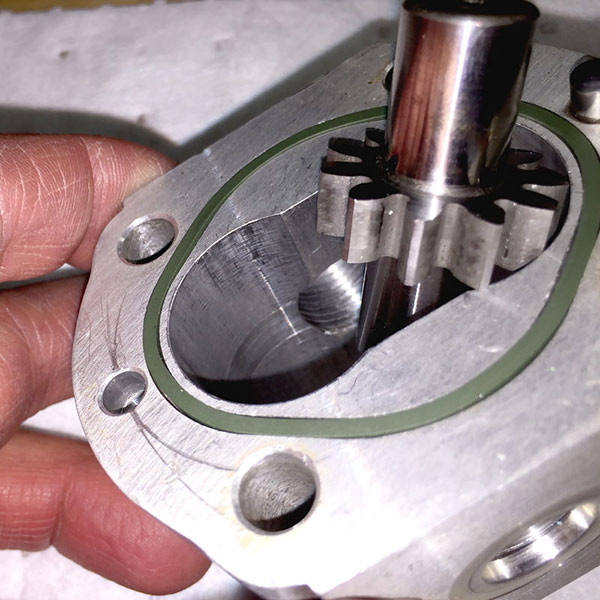

One symptom of hydraulic oil contamination is increased noise and vibration levels. When the oil is contaminated, it loses its lubricity, leading to increased friction and wear between the hydraulic components in your system, such as the pump’s rotating group against its housing or wear components. The asperities across the worn parts cause localized noise, chatter, and vibration above and beyond the usual noise generated by pumps and other components.

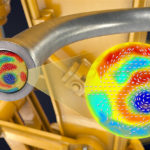

Image courtesy of CD Industrial Group/LunchBox Sessions

Although likely noise increases slowly over time as components become worn or scored, sometimes the rapid rise of offensive sounds signals the pump or motor are not long for this world. Awareness of your hydraulic system’s typical sound signature provides you with an advanced warning to allow maintenance staff to step in before complete failure occurs.

Hydraulic systems rely on clean hydraulic oil to best take advantage of input energy from the prime mover. However, when the oil is contaminated, it causes a reduction in performance as gaps and clearances open up between the precise pistons, spools, vanes or other parts. The increased clearances result in slower movement, less force, and reduced precision because fluid lost to leakage is wasted as pure heat. Such reductions in efficiency reduce productivity and increase energy consumption while hot oil bypasses to the reservoir rather than the actuators.

Paying attention to your hydraulic oil’s color also provides contamination insight. When hydraulic oil is contaminated with water, it may change color or appear foggy, which are sure signs that excessive saturation has taken hold. However, the oil may also appear darker brown color if oxidation burned the oil or resulted in circulating sludge. If you notice any discoloration, it is essential to have the oil tested to determine the source of the contamination and then correct the problem before it’s not too late.

Image courtesy of CD Industrial Group/LunchBox Sessions

In addition to color change, contaminated hydraulic oil may emit a foul odor. This odor indicates your oil is contaminated with bacteria, which can cause further damage to the hydraulic oil, or even the system components, if left unchecked. Bacterial contamination is more common in water-based fluids, although it may still occur in mineral-based oil highly saturated with water.

Hydraulic oil contamination is the number one cause of damage to hydraulic systems and components, leading to reduced performance, increased maintenance and repair costs, and safety hazards. Therefore, it’s essential to identify the most common symptoms of hydraulic oil contamination and take steps to prevent further damage. If you notice any of the symptoms listed above, it is important to have the oil tested and to take corrective action to address the contamination. In addition, regular oil analysis and maintenance can help prevent contamination and ensure optimal hydraulic system operation.

Excellent article!