During a press conference on March 15 at IFPE, Hallite showcased its three new seal offerings — the 683 low friction rod seal, 565 precision bearings, and the 777 piston seal.

The three new products help spotlight Hallite’s commitment to innovation, education, product testing in partnership with MSOE, and sustainability.

“We recognize that sustainability has never been a more relevant, important, or debated topic,” said Andrew Iddeson, Global Technical Director for Hallite. “So, by optimizing our manufacturing processes, we reduce waste and optimize product deliverables. This is the case with the design of the 565, which is a new range of Hallite bearings.”

The 565 is a high-precision, molded bearing and it is innovative in its availability in sustainable materials, such as certain advanced polymers and renewably sourced nylons. It will also be available in reinforced polyoxymethylene (POM) for applications that operate in water-based fluids.

“Precision bearings tend to be a machined product but what we’ve invested in is innovative tooling which enables us to mold these products to a high degree of precision. High degree of precision in a bearing ensures that the cylinder in which it’s assembled, the radial displacement’s managed,” Iddeson said. “In managing those radial displacements and minimizing those radial displacements, we can extend the life of the seal. The seal is under less duress and can last longer.”

Hallite invested in more efficient tooling to reduce sinking that may happen to typically molded bearings. The tooling helps ensure there is no waste as well, Iddeson, said, but is considered a high-end, large volume component.

The final 565 bearing product comes off the tool with no waste. The material (in the exampled pictured) is a glass-filled nylon. Nylon can also use bio-content or even recycled material, he concluded.

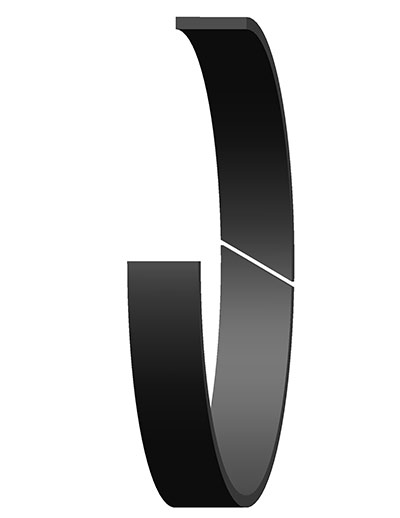

The 683 low friction rod seal is an asymmetric single-lipped rod seal designed with precision-trimmed sealing lips to provide a dry sealing solution in light and medium-duty applications. Its design provides low friction to help lower fuel consumption, reduce emissions and optimize performance.

Chuck White, Global Product Development Manager, Hallite Seals International, Ltd., said the 683 is suited to medium and light-duty applications. The lips help reduce the friction on the rod seal and reduce energy consumption while increasing seal life. “We’re committed to sustainability, so we’re not only looking at leakage and less friction but also how we manufacture it,” White said. “We’re looking at materials that are less environmentally harmful, (require) less energy in the manufacturing process, and also the ability to recycle at end of life.”

White says all products must meet Hallite’s Life Cycle Analysis, which is used in all new product launches. Then the company works with MSOE’s testing labs to ensure stability and durability.

Finally, the 777 reintroduces the double-acting, energized piston seal. It has been redesigned to include imperial sizes to fit a range of industry-standard grooves. In addition, it is now available in more cost-effective material options for less demanding applications.

Ryan Webster, VP Sales & Marketing, Hallite Seals America, said that Hallite has added innovations to the 777, which was originally launched in 2017. Like the 565 bearing, key innovations come with new tooling, he said. “We found a way to produce these in a more sustainable fashion, where we can output parts quicker, more efficiently with better quality,” Webster said. “This all leads to a better product.”

The new material options allow Hallite to bridge a gap across all the markets in terms of lower price points. “Hallite has a range of piston seals now that does all the inch grooves as well as the metric grooves,” Webster noted, including NFPA and ISO standards.

“We measure our materials to see how sustainable we are. We are on a roadmap to be 100% sustainable. It’s many decades on the path,” Iddeson concluded. “Our customers are on the same path. They want the steel that they use in their cylinders to be more sustainable. They want the fluids to be more sustainable. And as a consequence, we as a seal maker, need to be able to provide that.”

Hallite

hallite.com/ifpe2023

Leave a Reply