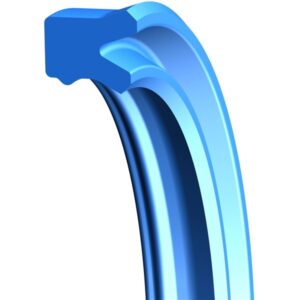

Sustainability continues to trend across the fluid power industry, as design engineers must develop more efficient products to meet the industry’s sustainability needs. Hydraulic seals, though relatively small in design, play a huge role in waste, emissions, efficiency, and overall environmental impact.

At IFPE, companies such as Hallite will introduce new products that demonstrate sustainable manufacturing by using non-polluting processes, conserving energy and natural resources, and creating economically sound and safe products for employees, communities, and consumers. Innovations in hydraulic sealing product testing are also a major focus for Hallite at the show. The company will have dedicated space in its booth to demonstrate and discuss the value and impact of product testing.

The fluid power industry is also experiencing an uptake in custom sealing solutions to meet new and evolving design requirements.

“Customized seals, or at a minimum, ‘modified’ standard products, will see an increase in demand as manufacturers continue to innovate and increase application requirements,” said Michael Cook, global segment director, off-highway and marketing Americas segment manager, fluid power, Trelleborg Sealing Solutions.

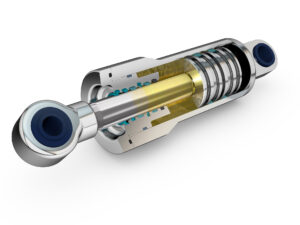

Cook expects market demand to grow for solutions differentiating performance, such as low friction, greater energy efficiency, and energy density (higher load in less space). It is critical for hydraulic seals to maintain existing performance expectations, as automation allows construction and agriculture equipment to operate for longer periods of time with potentially higher speeds, increased pressures, and wider operating temperatures. With renewable energy equipment, such as wind turbines, increased speeds and heat generation require further optimized sealing approaches to ensure consistent operation between maintenance cycles. Additionally, functional integration, higher speeds, and greater accuracy will drive advances in solutions.

However, exactly how sealing approaches will change with mobile electrification, efficiency, and other key trends is uncertain.

“Replacing an internal combustion engine with an electric motor/drive system will certainly change sealing requirements and likely reduce the number of hydraulic seals needed,” said Cook. “For linear applications, given the power density requirements in many mobile applications, we are likely to see more of an integration of electric technology with existing hydraulic infrastructure. In this case, we would expect to see the sealing approach stay mostly consistent. In smaller equipment that can be fully electrified, the linear sealing opportunities will likely be reduced as electromechanical actuators operate much differently than hydraulic cylinders. Also, electrified solutions will require protection against harsh environments.”

Cook also noted that material development will be critical to ensure materials compatible with new fuel sources, such as hydrogen, are available. Seals that promote system efficiency, limit leakage, and facilitate extended equipment uptime and life will be essential to manage overall environmental impact. In the long term, seal materials will likely be reviewed to see where environmentally friendly or recyclable variations can be developed and production waste can be limited or repurposed.

Over the past couple of years, supply chain issues have forced design engineers to deepen their knowledge of materials and how components interact. Exploring alternative seal solutions to keep production and systems running without compromising quality and operation has become an ongoing task.

Since no one knows what to expect from supply chains moving forward, it’s best to be prepared and “think outside the traditional supply box,” as Corey Holloway, sales manager for anyseals North America, stated. Holloway recommends investigating compatible and better-performing alternatives made with different compounds. For example, it’s possible that certain seal properties aren’t necessary for a particular application and can therefore be substituted with more readily available sealing products.

Holloway also noted that since inventory management is critical for maintaining production during supply chain fluctuations, many customers are turning toward suppliers with virtual warehousing in case they need to make a product switch quickly.

Hallite

hallite.com

Trelleborg Sealing Solutions

trelleborg.com/seals

anyseals Inc.

anyseals.com

Leave a Reply