Des-Case Corp. has announced the launch of a new remote diagnostic monitoring subscription plan for industrial lubricated assets where customers can have peace of mind knowing the lubricant health, cleanliness and humidity inside their critical assets have real-time monitoring by a team of experts.

“Des-Case has innovated and manufactured solutions that keep lubricants clean and dry for more than 37 years, so adding sensors to those solutions, tying them back to an intuitive and easy-to-use IsoLogic software platform and wrapping it all with a diagnostic monitoring service was a natural enhancement to our portfolio to become a part of the rapid emergence of the digital plant,” said Company President and CEO, Brian Gleason.

The company’s We Monitor package offers a bundling of its solutions for one low monthly price (billed quarterly) — the remote monitoring service delivered by a team of analysts and lubrication experts providing real-time advice, the edge gateway devices, the connected desiccant breather plus replacement cartridges, and lubrication training and consulting all wrapped into one plan. Additional sensors per asset can easily be added on to the package to monitor an array of lubricant conditions.

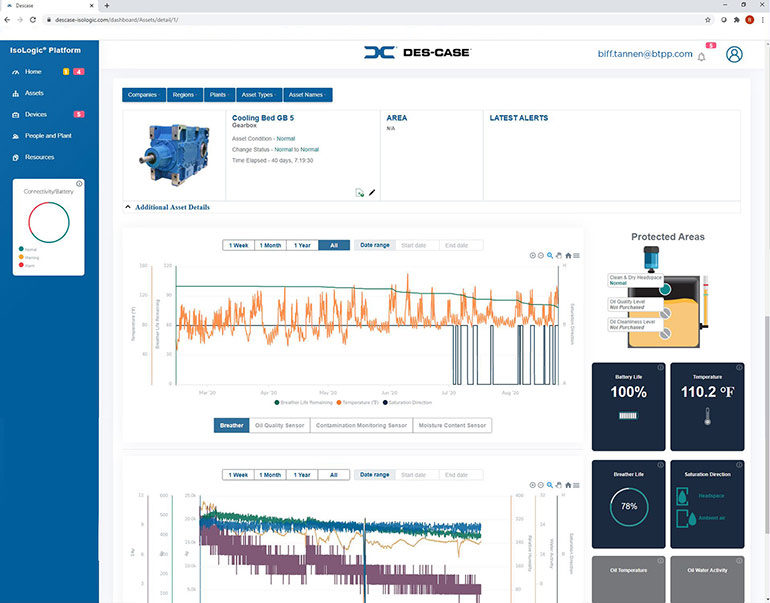

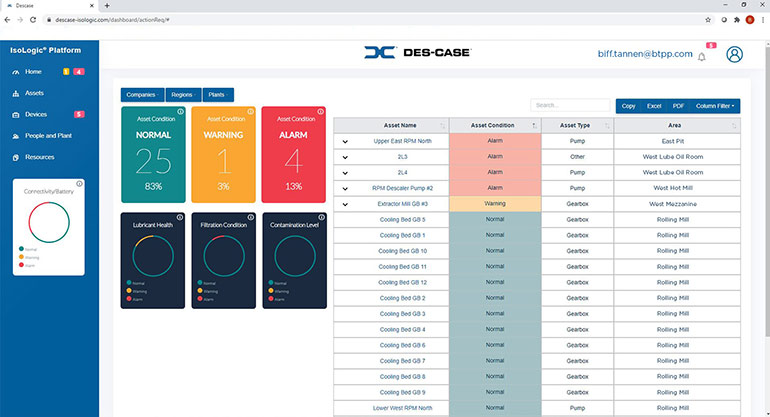

The new IsoLogic platform and app provide enhanced features and functionality, most notably the ability in the platform to quickly view asset status across the plant or multiple locations, lubricant condition status, connectivity status and dig deep with multi-layer trend analysis per sensor per asset. Email alerts notify the customer when an alarm or warning goes off, followed up with a call to provide diagnostic instructions and actions from a lubrication expert. Monthly, quarterly and annual reports and presentations are provided to help show ROI, report on asset trends and deliver lubrication best practices advice for a holistic and sustainable program.

Stephanie Schaffer, VP of Connected Solutions & Marketing, described how “the new reality of our working environment – from home or in plant with limited resources – is a large catalyst for the need of this remote monitoring service.”

“Survey results show companies don’t have the in-house resources, the time or knowledge necessary to analyze and interpret the data they are receiving across multiple data points, and lubrication expertise to predict and prevent failures and sustain best practices. That’s why we want to provide more than just the sensors and software, but also incorporate training, consulting and our decades of in-house knowledge in lubrication. No two reports will be the same because this service is truly tailored to the customer and solving their unique challenges. Our objective is to be a partner with each company year after year, working together to prevent downtime, reduce maintenance costs and provide continuous training for employees,” Schaffer said.

The We Monitor — and Enterprise packages for companies with 100 or more assets — will roll out in North America first, with plans to bring it to other countries in the near future. Another option is the You Monitor package where customers can purchase the sensors and edge gateway device and monitor the data on their own via the IsoLogic platform or hardwired into their own CMMS.

Des-Case Corp.

descase.com

Leave a Reply