Hydraulic cylinders are used to perform work in a bevy of different situations and applications every day. Whether it’s the plow truck clearing the road, a utility vehicle fixing an electrical issue, or a compactor at the local recycling center—hydraulic cylinders are in motion almost everywhere.

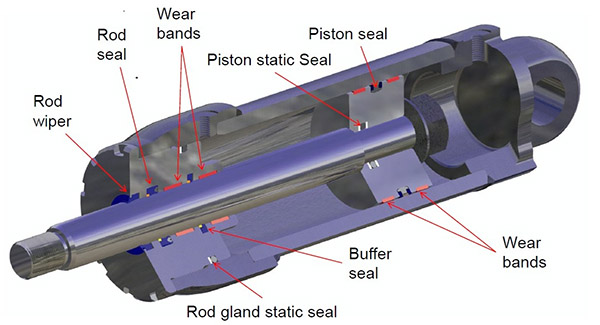

With hydraulic cylinders, there is more than meets the eye. To contain the pressurized fluids in a hydraulic cylinder system and keep it in motion, a complex configuration of high-performance seals in two basic categories are required: (1) static seals and (2) dynamic seals (supported by guide rings).

Let’s examine some specific types of seals in each category. Static Seal. A seal that is not subjected to any type of movement when pressurized. This includes O-rings, D-rings, back-up rings, cover seals and gaskets. One of the simplest examples of a static seal is the O-ring. O-rings are very versatile and available in various sizes. When placed into the cylinder housing and squeezed by a casing, the O-ring creates a physical barrier between the housing and the casing. Commonly used with back up rings for pressures over 1500 p.s.i., O-rings in nitrile rubber (NBR), fluoro rubber (FKM) and ethylene propylene diene (EPDM) are suitable for use in a multitude of different mineral oils, water and water-based fluids and air. Other compounds such as Polyurethane (TPU) and silicone also have uses in a static environment.

Dynamic Seal. A seal that is subjected to axial and/or radial movement when pressurized. This includes piston seals, rod seals, rotating seals, wipers/scrapers and oil seals. Piston seals prevent pressurized fluid from leaking across the piston as the system pressure pushes the piston and rod assembly down the cylinder bore. Rod seals hold pressure in the cylinder by preventing fluid from leaking out. Leakage through the rod seal can reduce equipment performance and in extreme cases cause environmental issues. Wipers, also known as scrapers, prevent contaminants such as dirt, dust and moisture from entering the cylinder as they retract back into the system. Contamination can cause significant damage to the rod, cylinder wall, seals, and other components, and is one of the primary causes of premature seal and component failure in a fluid power system.

Guide Ring. Resin-bonded fabric, guide tape and engineered plastics that guide the piston in the cylinder bore and rod in the cylinder head of a hydraulic cylinder. Guide rings are used to prevent damage from side loading as they prevent metallic contact between axial and rotational components from contacting one another. In addition, guide rings also help to trap contaminants sub-surface before they reach the most critical sealing elements.

Choosing the right seal is critical in assuring the best performance for hydraulic cylinder applications.

Contributed by Ryan Webster, Director of Engineering, Hallite Seals International

In rebuilding a brake caliper, I discovered that one piston has a seal with a “V” shaped cross section and one with a square section. The other piston had these seals reversed. Your article provides some information to help me decide which seal goes where, but a diagram showing the shapes of seals used for different purposes would make the article even more helpful.

Good answer