The European Union aims to expand the capacity for wind power generated at sea to at least 60 GW by 2030. With its sealing solutions for the foundation structures, Freudenberg Sealing Technologies helps ensure that new wind turbines reach a service life of at least 30 years or more despite the rough conditions at sea. The highest wind velocity … [Read more...] about Freudenberg Sealing Technologies improves service life of offshore wind turbines

freudenberg

Material simulation, testing improve lifespan of offshore wind turbines

Freudenberg Sealing Technologies has developed an advanced testing procedure and simulation methodology that, in combination with the company’s Ventoguard portfolio of elastomeric materials, offers performance improvements and better longevity in offshore wind energy component applications. The material simulation process helps to identify optimal … [Read more...] about Material simulation, testing improve lifespan of offshore wind turbines

Freudenberg expands engineering services

As a manufacturer of engineered sealing applications around the world, Freudenberg Sealing Technologies is constantly pursuing ways to provide its customers with enhanced product quality and better service. To that end, the company has opened a dedicated engineering service center in North America as part of its global radial shaft seal … [Read more...] about Freudenberg expands engineering services

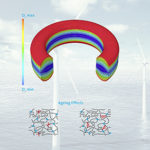

Freudenberg’s new method shows how static seals actually age

The seals used in plant engineering must have a very long service life. Once they are installed — to protect offshore wind turbine towers from salt corrosion, for example — customers (typically) require that they perform perfectly for more than 20 years. The service life of a seal is limited on the one hand by setting or stretching (physical … [Read more...] about Freudenberg’s new method shows how static seals actually age

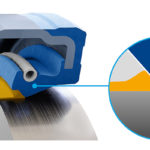

New rotary shaft seal coating reduces wear and shaft runout

The optimum function of rotary shaft seals depends on many factors. One of them is the wettability of the sealing lip. This parameter plays a particularly important role with synthetic lubricants such as polyglycol. If wetting is too low, not only does wear on the sealing lip increase, but the contact with the rotating shaft can also damage the … [Read more...] about New rotary shaft seal coating reduces wear and shaft runout

Wedge-shaped seal for shock absorbers simplifies installation, reduces friction

Shock absorbers ensure that a car’s wheels stay on the road, making them a key safety element in any model. A new design concept from Freudenberg Sealing Technologies simplifies the installation of the seal between the housing and the piston rod inside the absorber. The wedge-shaped seal also reduces friction, leading to less wear. If a vehicle … [Read more...] about Wedge-shaped seal for shock absorbers simplifies installation, reduces friction

Freudenberg upgrades quality process with new vision inspection units

Freudenberg’s inline spring inspection machine, a packaging marvel no bigger than a standard microwave oven, scrutinizes 6-12 mm diameter garter springs at a rate of four per second for defects including kinks, gaps, irregular diameters and poorly joined ends. The machine segregates defective components out of a typical batch of 10,000 springs and … [Read more...] about Freudenberg upgrades quality process with new vision inspection units

HAGC Seal systems for hydraulic automation gage control cylinders

In the steel industry, the hydraulic automatic gauge control (HAGC) cylinders used in mills pose a big challenge to sealing systems, which need to handle high extrusion resistance and maintain low friction at the same time. Freudenberg Sealing Technologies will exhibit its range of seal systems and materials for HAGC applications and more at the … [Read more...] about HAGC Seal systems for hydraulic automation gage control cylinders

Freudenberg Perfect Cylinder program simplifies cylinder and sealing selections

With the goal of helping customers reduce the manufactured cost of hydraulic cylinders while optimizing performance and lifespan of their production equipment, Freudenberg-NOK Sealing Technologies has announced its new Freudenberg Perfect Cylinder program, a collaborative engineering and design approach with customers. Freudenberg-NOK, Plymouth, … [Read more...] about Freudenberg Perfect Cylinder program simplifies cylinder and sealing selections

Chapman named global sales head of Freudenberg’s automotive business

As of May 1, 2019, Matthew Chapman will take over as the new President of Sales and Marketing for the automotive business of Freudenberg Sealing Technologies. The company is part of the Freudenberg Group and the global market leader in sealing technology and a supplier to the automotive industry. Chapman succeeds Rainer Joest, who is retiring after … [Read more...] about Chapman named global sales head of Freudenberg’s automotive business