Freudenberg’s inline spring inspection machine, a packaging marvel no bigger than a standard microwave oven, scrutinizes 6-12 mm diameter garter springs at a rate of four per second for defects including kinks, gaps, irregular diameters and poorly joined ends. The machine segregates defective components out of a typical batch of 10,000 springs and then bags and labels the remainder for tracking and shipping to customers.

Despite the minimal cost of each spring — a couple of pennies apiece — the first inspection unit installed at the company’s Bristol, N.H., manufacturing plant is already lowering the company’s costs.

Plant personnel note that scrap rates have dropped, variability in the inspection process has been reduced, lost production time on the line has been cut and working conditions have improved. Prior to installation of the inspection unit, employees used a light table and magnifier to inspect springs manually for defects. Under this process, thousands of tiny springs were visually checked on the light table and when a certain number of defects in the batch was detected, the entire batch was scrapped.

Addressing defects as quickly as they are detected

Significantly, the new inspection technology is also eliminatingthe possibility of expensive customer recalls. As the unit identifies and tracks the defects it encounters, software transmits this information back to the spring making machine. When too many defects are detected, the inspection unit automatically shuts down the spring making machine so misalignments and other issues can be addressed.

Defects can be addressed nearly as quickly as they are detected, said Robert Scavuzzo, VP of Global Advanced Manufacturing Technology for Freudenberg Sealing Technologies. This dramatically increases the company’s ability to eliminate production of defective springs in the first place.

“You will never inspect quality into a component,” Scavuzzo said. “You have to prevent defects in the first place. This unit makes it possible.”

Freudenberg is developing a dashboard in conjunction with the inspection units that will collect data and allow operators to see which machines are operational and which need adjustments on one screen. Such visual capability is a powerful tool in today’s zero-defect environment, and is based upon proprietary automatic vision control technology recently developed by Freudenberg.

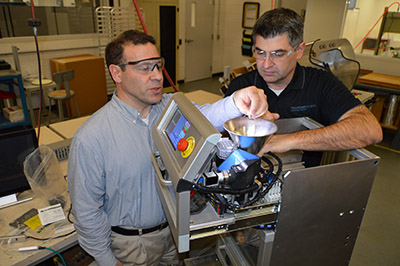

The company’s Flexible Image Process System uses a series of algorithms to process a part for defects in less than 50 milliseconds. Based on the algorithms, the inline spring inspection unit inspects springs for eight different dimensional and surface defects. This technology is at the heart of the inspection unit’s automated vision control (AVC) capabilities. But the units also required other technology innovations to go from concept to operational design, noted Scott Sulhan, a senior engineering expert specializing in robotics and machine design at Freudenberg.

In developing a prototype inspection unit, Sulhan was handed an extensive list of manufacturing requirements. A small, compact unit was imperative in order to fit the inspection units under manufacturing machinery. The units needed network capability that would allow operators to track the system on a large plant screen and on their cell phones. A small electronic dashboard that showed statistics and data needed to be incorporated into the unit. In addition, a mechanical chute that could move the springs quickly and smoothly through the inspection process and into separate bins needed development.

Using additive manufacturing to tackle challenges

The chute design that Sulhan developed incorporates intricate channels and extremely thin parts to move the tiny springs smoothly through the inspection process. Sulhan turned to additive manufacturing to help the company achieve perfectly machined success.

“These componentswould have been incredibly difficult to machine using traditional methodologies because of their size and the intricacy of their design,” Sulhan said. Instead, Sulhan asked colleagues who were working with Additive Manufacturing equipment to help him develop the necessary components. The team worked to manufacture a variety of intricate parts layer by layer, saving considerable time and money. Additional component adjustments were designed and manufactured quickly, again using Additive Manufacturing, once the prototype was assembled and potential mechanical issues were discovered.

Freudenberg will machine and build the new inline spring inspection units at its Machine Tool Center (MTC) in Northfield, N.H.

Equally important, with the successful development of a highly precise, remarkably small inline spring inspection unit under its belt, Freudenberg intends to develop larger inspection units for use in other manufacturing operations. The Flexible Image Process System and additive manufacturing methodologies will be incorporated into these efforts as well.

“Freudenberg is proactive and innovative in how it maintains quality and value on behalf of the customer,” Scavuzzo said. “Advance Vision Control technology is very expensive. But through MTC, Freudenberg can rely on its own technical engineers, scientists, program developers and machinists to supply state-of-the art inspection equipment and systems that meet customer demands while making widespread installation possible within our manufacturing plants.”

Freudenberg Sealing Technologies

www.fst.com

Leave a Reply