As a sealing product, O-rings have been a very cost-effective and simple choice since the 1940s. However, there does seem to be some mysticism about how these relatively simple shapes actually function. Robert W. Keller, PhD, Director of Technology Sales at Freudenberg-NOK Sealing Technologies explains that in reality, the simple physics and the mathematics really give an accurate picture of how O-rings seal.

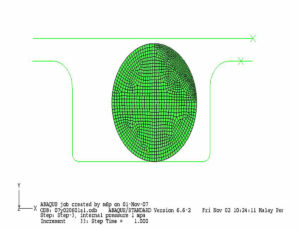

“In the Figure 1 below, we have an O-ring ‘face seal’ application ready to be assembled. As the mating flat face approaches contacting the O-ring, we will end up with the situation where the flat face initiates contact and the contact pressure on the O-ring will be the force applied divided by the contact band area. The contact band on the O-ring will be the circumference of the circle at the contact point multiplied times the width of the contact.”

Contact and load

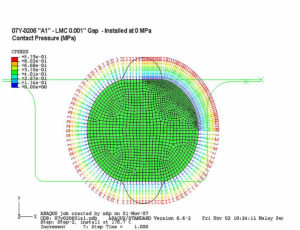

“But wait! It is not that simple. The width of the contact is really 0,” he says. “That is correct and we will end up with infinity which is division by zero. That is the key to understanding how O-rings work—at initial contact, the load is infinite and the O-ring MUST deflect (Figure 2)”.

Keller goes on to explain that other shapes, like rectangular or square cross section seals, do not have this theoretical infinite load at contact and they may, or may not deflect and seal at low assembly force.

“Notice in Figure 2 the contact pressure profile that is responsible for the function of the O-ring. Therefore, theoretically, any O-ring in any material must deflect and seal since the initial contact pressure would approach infinity,” he said.

Misconceptions

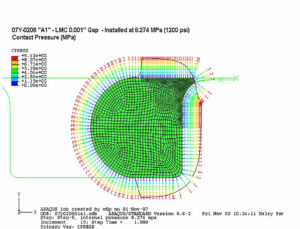

Keller said that there is also the misconception that when the system pressure exceeds the initial peak contact pressure, the O-ring will leak. “This ignores the deformation of the O-ring with system pressure, especially for relatively soft materials like vulcanized rubber.”

“In Figure 3, we applied 1,200 psi system pressure to the O-ring assembled in Figures 1 and 2. Figure 2 peak contact pressure is 136 psi (0.935 MPa), so that 1,200 psi system pressure should cause leakage if the theory applies where system pressure exceeding initial contact pressure will cause leakage. However, the vulcanized rubber O-ring deforms under pressure and pushes into the extrusion gap preventing system leakage (see Figure 3). The O-ring contact pressure has increased to 1,365 psi (9.42 MPa) which exceeds the applied system pressure and the O-ring continues to seal.”

O-rings are one of the most common seals used in machine design applications. They are used in all types of both static and dynamic applications. Having a good understanding of how they work will benefit any design engineer.

By Joyce Laird

Leave a Reply