By Corey Holloway • Sales Manager, anyseals North America

The painful reality is that supply chain challenges are the new normal. Unfortunately, current world conditions have resulted in unavoidable shortages and unforeseen delays in the global availability of all manner of supplies, and there is no clear solution in view. Nevertheless, sealing applications requiring O-rings, rotary sealing products like oil and radial seals, and various commonly used hydraulic and pneumatic seals are in constant demand. When these items are hard to find or simply unavailable, what options do industrial customers have?

Here are some technical tips to help maintain productivity.

1. Investigate suitable alternatives

There are many industrial sealing products with compatible or slightly better performing alternatives. However, when customers are willing to think outside the traditional supply box, several effective solutions may emerge. For example, the standard nitrile butadiene rubber (NBR) oil seal is popular for various reasons. It offers high abrasion resistance and tensile strength and high resistance to petroleum-based oils and fuels, silicone greases, hydraulic fluids, water, and alcohols. Low gas permeability and compression set are additional characteristics. As an alternative, fully coated hydrogenated rubber (HNBR) can be used in the right size and dimensions because it offers comparable features with slightly different compounds.

With these facts in mind, a customer seeking the standard NBR product may find the FDA/NSF 61 approved NBR 70 O-ring appropriate for the application. The price is slightly higher, but FDA/NSF 61 compounds are in stock in many sizes in most cases. Size and color alternatives should also be explored. For example, an oil seal with a 10-mm width can potentially be replaced with a 12- or 8-mm width seal. Additionally, FKM in unconventional colors (i.e., green, black) is often in stock.

Style alternatives are also worth exploring. For example, a rubber-coated double lip style may serve as a suitable replacement if a customer requests a specific seal for an application, such as a rubber-coated single lip NBR oil seal. Another option may be a metal-cased O.D. seal with the exact measurements.

2. Know how compounds function

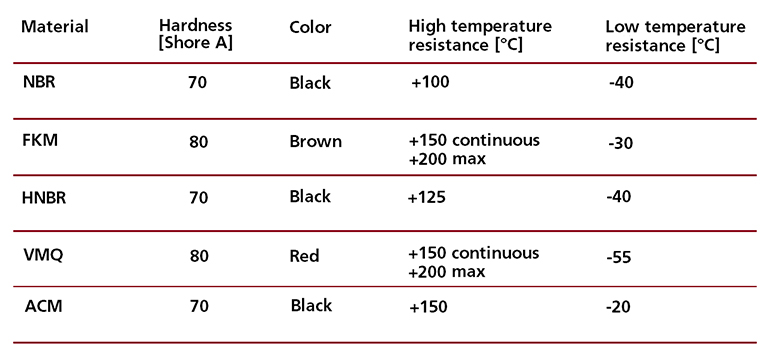

If a customer requests a material compound with a temperature range of –65° to 270°F, it may be pertinent to re-evaluate whether this exact range is necessary for the application. If there is some flexibility, an alternative standard compound with a range of –40° to 250°F, for example, may be sufficient. Using the oil seal as a practical example, the temperature load to which the seal is subjected consists of the temperature of the medium, e.g., oil temperature and the excess temperature induced by the friction between the sealing edge and the shaft. As illustrated in the chart below, multiple materials may meet a customer’s need, although they may not have been considered initially.

Temperature compatibility, while important, is just one of several aspects to consider when seeking to fill the need for a sealing product in short supply. Understanding the complete functional threshold of a compound lends itself to more flexibility for brands with comparable specifications. A peer brand with similar performance characteristics may be used temporarily if a preferred brand is unavailable.

3. Re-evaluate your inventory management approach

The greatest possible availability of the various standard seals requires substantial warehouse and picking capacity. This makes a well-established inventory management system exceedingly critical, especially when supplies are low. Customers benefit from a secure product source procured from reputable, certified production manufacturers.

Many are partnering with suppliers that use the virtual warehousing concept to meet this objective. This approach helps suppliers better ensure the availability of a wide range of products when customers need them. And customers improve their productivity and delivery times on all products available.

Suppliers like Brecksville, Ohio-based anyseals inc., partner with hundreds of distributors with similar product needs by providing more than 400 million individual sealing products in more than 65,000 sizes. With such a vast offering, the supplier is more likely to have a product, or a comparable alternative, in stock when a customer needs it.

4. Be realistic

No one can predict, with complete accuracy, how the supply chain will flow in the future, so a realistic view is imperative. The best thing to do right now is to be as flexible and adaptive as possible. Partner with a reputable supplier to help navigate the chaos when supplies are low and collaborate on preparedness when inventories are up. Finally, keep a finger on the pulse of developing events impacting the procurement of relevant raw materials and the shipping and port resources required by suppliers. These are strong indicators that allow the industries that depend on sealing products to make informed operating decisions.

anyseals Inc.

anyseals.com

Leave a Reply