Fluid-power engineers who design sealing systems always have to weigh the trade-off of minimizing leaks versus shorter operating life. In hydraulic applications, seals made from two polyurethane components could resolve the conflict between sealing tightness and strength. Freudenberg Sealing Technologies, Weinheim, Germany, is now conducting research on rotating seals in which polyurethanes are bonded with new high-performance plastics.

Hydraulic applications put extreme demands on sealing systems that must prevent the escape of hydraulic fluid. Because systems often run at high pressures, the seal lip is usually made of highly flexible and elastic materials. These materials—in a hydraulic cylinder, for example—are positioned optimally against the rod. In other cases, sealing elements must not be forced into the so-called extrusion gap, the clearance between the rod and housing that allows rod movement. Quite hard materials with high rigidity are suited for this role.

Rotating hydraulic seals are used in rotary feedthroughs in machinery that does not rotate continually but, rather, perform turn and swivel motions. The rotating claws of tree-harvesting machines in the forestry industry are one example, as are the rotatable superstructures of hydraulically powered crawler excavators. Here a rotary feedthrough facilitates the hydraulic fluid’s sealed flow between the fixed and rotating bodies under high pressure.

Previous systems have consisted of an O-ring, square ring or X-ring which seals against the housing as a static contact element; and a slide ring, where the shaft glides along its rotational movement and, under hydraulic pressure, creates a sealing effect.

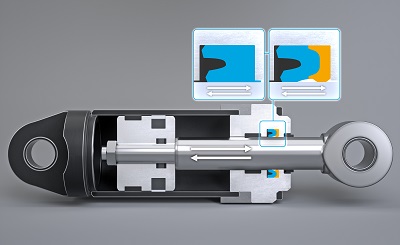

Until now, to solve these conflicting objectives, seals consisting of two elements have been used—with the disadvantage that they move toward one another, and the hard element can “eat away” at the softer counterpart. For several years, Freudenberg Sealing Technologies has manufactured rod seals consisting of just one element made from two different polyurethanes. The lip material is optimized for high dynamic sealing action, and material at the opposite (pressure) side is geared to the greatest possible distortion resistance.

The company is now researching processes in which polyurethanes can be bonded to high-performance plastics. Such combinations can withstand even greater loads and exhibit significantly longer lifespans.

But in a sealing system made of two elements, there is the danger that the slide ring might be carried along with the shaft. The two sealing elements would then move in relation to one another and could thus face increased wear. The higher the stresses from pressure and temperatures in a hydraulic system, the greater the danger. Freudenberg wants to solve this problem with new firmly joined, two-component seals made of polyurethanes and high-performance plastics. Because the individual components of the rotational seals no longer rub against one another, the seals can be used with an expanded power spectrum and thus in a broader range of applications.

In developing the new rotating seals, Freudenberg Sealing Technologies relies on its experience with two-component rod seals for hydraulic cylinders. The requirements on the sealing system are similar but, in those cases, the seals must withstand linear movement—not rotation—because the rod in a hydraulic cylinder moves back and forth.

To produce the two-component seals, polyurethanes with different hardnesses are bonded to one another in an injection-molding process. The bond benefits from the fact that the individual components come from the same material family. One challenge that the developers of the new rotating seals face is transferring the process to two-component seals that combine substances from different material families.

For manufacturers of hydraulic cylinders, the main advantage of the current two-component rod seals is that they allow greater tolerances in the design of pistons and rods. The seals exhibit greater strength with regard to the extrusion gap. As a result, the gap can be larger than possible in conventional sealing systems. This also lets the sealing ring mount more easily. Freudenberg Sealing Technologies now wants to develop this design flexibility for manufacturers of equipment with rotary feedthroughs.

Freudenberg Sealing Technologies

www.fst.com

Leave a Reply