By Josh Cosford, Contributing Editor

Hydraulic systems play a critical role in various industries, powering heavy machinery and equipment with precision and efficiency. The performance and longevity of these systems heavily rely on the cleanliness and quality of the hydraulic fluid. Contamination in hydraulic fluid can cause significant damage to the system, resulting in reduced productivity, increased maintenance costs, and potential safety hazards. This is why hydraulic systems that use phosphate ester or water glycol fluids require special hydraulic filters designed to address the unique challenges posed by these fluids.

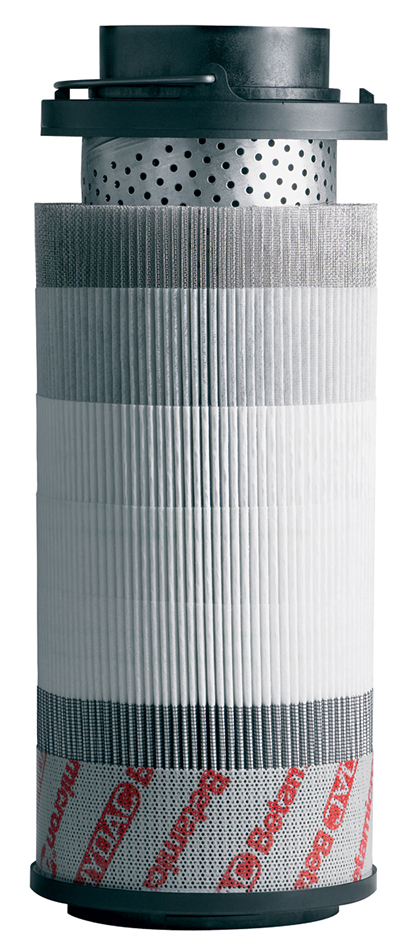

and elements, such as these from Hydac, can be used with most of these fluids.

Phosphate ester fluids are commonly used in applications where fire resistance and high-temperature stability are crucial. While phosphate esters possess several desirable properties, they are also susceptible to increased acid levels over time. As the fluid ages, acids can form due to oxidation and thermal degradation, leading to corrosion and damage to hydraulic components. Therefore, hydraulic filters used in phosphate ester systems must have the ability to reduce acids, as well as alcohols and sludge, to maintain optimal fluid cleanliness.

Hydraulic filters for phosphate ester fluids employ advanced filtration media and technologies to remove contaminants effectively. These filters are designed to capture and neutralize acids that can cause corrosion, protecting critical system components from degradation. Additionally, they can remove alcohols and sludge, which can accumulate in the fluid and impair its performance. By maintaining the cleanliness of the phosphate ester fluid, these specialized filters help extend the service life of hydraulic systems and ensure their reliable operation, especially when it comes to advanced components such as servovalves.

Water glycol fluids, on the other hand, are often used in applications where fire resistance and environmental considerations are essential. Although water glycol fluids offer advantages such as high viscosity index and biodegradability, they also present unique challenges regarding contamination. Water in the fluid can promote bacterial growth, potentially damaging the fluid and system components. Therefore, hydraulic filters for water glycol fluids must be capable of addressing this specific contamination issue.

Specialized hydraulic filters for water glycol fluids are designed to prevent bacterial growth and maintain fluid cleanliness. These filters incorporate features such as bacteriostatic additives or technologies that inhibit bacterial growth, effectively mitigating the risk of contamination. By preventing bacterial contamination, these filters help preserve the integrity of the water glycol fluid and ensure the optimal performance and longevity of hydraulic systems.

Regular maintenance and monitoring of hydraulic filters are essential for systems that use phosphate ester or water glycol fluids. Always select filters with bypass indicators, which signal the maintenance team to change the filter before it opens the bypass valve, negating filtration altogether. Per the manufacturer’s recommendations, routine filter inspections and replacements are necessary to maintain their effectiveness. Additionally, conducting regular oil analysis to monitor fluid condition and identify potential contamination issues can help prevent damage and ensure optimal hydraulic system operation.

Hydraulic systems utilizing phosphate ester or water glycol fluids require special hydraulic filters to address the unique challenges associated with these fluids. Phosphate ester fluids are prone to increased acid levels, necessitating filters capable of reducing acids, alcohols, and sludge. Water glycol fluids pose the risk of bacterial contamination, requiring filters designed to inhibit bacterial growth and maintain fluid cleanliness. Hydraulic systems can operate efficiently by utilizing these specialized filters and implementing proper maintenance practices, minimizing downtime, and reducing maintenance and repair costs.

Leave a Reply