It’s a fact of life that regardless of how well a hydraulic seal is engineered or how durable the compound, all hydraulic seals will fail at some point. Seals are by nature much softer and less durable than the metal components that they contact.

Kenneth James, Mechanical Engineer at MFP Engineering reminds all design engineers that a seal can have a wide variety of geometries. “They range from the simple, round elastomer O-ring to multiple material assemblies and this seal geometry plays a large role in balancing sealing, friction, and wear,” he said. “Seals that permit no leakage tend to increase friction and wear out faster. Seals are also characterized as dynamic, which sees relative motion, or static which has no motion. Dynamic motion can consist of oscillation, rotary, or a combination of both—and affects the choice of seal geometry and material.”

Kenneth James, Mechanical Engineer at MFP Engineering reminds all design engineers that a seal can have a wide variety of geometries. “They range from the simple, round elastomer O-ring to multiple material assemblies and this seal geometry plays a large role in balancing sealing, friction, and wear,” he said. “Seals that permit no leakage tend to increase friction and wear out faster. Seals are also characterized as dynamic, which sees relative motion, or static which has no motion. Dynamic motion can consist of oscillation, rotary, or a combination of both—and affects the choice of seal geometry and material.”

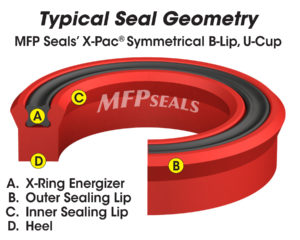

A common hydraulic seal style has sealing lips, heel and an energizer. The sealing lips are the primary contact points and their geometry influences how much hydraulic fluid is allowed past to lubricate the seal and how well the seal will exclude solid contaminants.

“The most reliable sealing lips are knife trimmed as opposed to net molded.” James said. “The heel is the solid, non-contact area which fills the remainder of the groove and provides stability for the seal. Many seals have an energizer such as an X-ring, O-ring or spring to pre-load sealing lips for superior low pressure performance. Seal height is defined as the height of a seal as it sits on a table top. Metal groove height is typically designed to be 110% of seal height.”

Selection is the number one problem

James notes that the main reason seals fail is due to improper seal selection. “Selecting a seal of improper geometry can result in unacceptably high friction or wear,” he said. “Improper material selection can result in material failure or rapid/accelerated wear.”

He goes on to explain that primary seal failure modes can be categorized into exceeding temperature specifications, incompatible fluids, and extrusion. Secondary reasons for seal failure are improper installation and contamination. “The best way to avoid seal failure is to have a complete understanding of the application before seals are selected,” he said.

“Exceeding the rated temperature for a seal material results in seal hardening, the formation of cracks, and deterioration. Hydraulic fluid temperature is usually measured in the reserve tank and may not reflect the actual temperature of the seals. Therefore, insufficient hydraulic fluid flow can result in localized heat in the cylinder. For example, a cylinder in a garbage truck compactor in a tropical environment can experience temperatures far above ambient causing the material to soften with heat and fail under pressure.”

“Another factor which manifests as high temperature damage is a seal being actuated faster than rated. The necessary interference inherent in a seal is subject to frictional heating and care must be taken to match material to speed of actuation.”

Incompatible fluid selection and other issues

Incompatible fluid selection typically causes the seal to swell and soften. The increased size of the seal can cause greater interference with the metal components increasing friction and heat generated by movement causing excessive heating damage. “The incompatible fluid may not necessarily be the hydraulic fluid itself, but can be a cleaning agent used before assembly or even a seal installation lubricant,” he said. “The possibility of water being introduced into a hydraulic system can also cause fluid incompatibility with some polyurethane seals.”

Extrusion is another issue. Extrusion in a seal shows up on the dynamic side of the heel of a seal. “It manifests as either cold flow material or small missing pieces. This can be caused by excessive system pressure, pressure spikes, or excessive extrusion gap also known as E-gap, which is the distance between the metal components to be sealed.”

Example: In the case of a piston seal, it is the distance between the cylinder bore and the outside diameter of the piston.

“E-gap can be minimized by utilizing new bearings or close tolerance guide rings. The incorporation of an anti-extrusion ring or a back-up ring made of a stronger material can help prevent extrusion by reinforcing the area most susceptible to damage. Pressure spikes can be caused by sudden impacts, like a back hoe breaking concrete,” James explained. “A buffer seal can be incorporated into a design to prevent pressure spike damage to the primary seal.”

Of course, as in many other areas, improper installation of seals can cause early or immediate failure. James warns that the use of sharp metal tools to install seals is a common method of damaging the sealing lip and creating a leak path. “Many seals are single acting and are directionally sensitive, so clear instructions to assembly personnel are important. Special tools can be utilized to ensure seal installation without damage.”

Contamination control

Contamination is also a leading source of seal failure. Contamination of hydraulic fluid with metal shavings from fabricating the metal cylinder components and other sources can scar the sealing lips and ruin the seal. “Metal shavings can also scratch the dynamic metal surfaces making a leak path around even a new seal. This type of damage would require refinishing of the cylinder bore or rod.” James recommends thorough cleaning of metal components before seal installation and using clean hydraulic fluid can reduce the chances of contamination.

Because of all the various things that can lead to early seal failure, it pays to keep a very close record of the history of all seals in hydraulic systems and implement a good, workable inspection regime. It pays to discover a potential failure in advance and fixing the problem before needing to do a complete repair/replacement in an emergency failure situation.

By Joyce Laird

One failure we have identified with seals is low temperature compression set. Some elastomers will take a low temperature compression set that is higher than the high temperature compression set.

We had a lab test a 70D HNBR rubber and 80D Nitrile rubber to ASTM D395B where the material is held at 100°C / 212°F for 22 hours. The HNBR had a 12% compression set, the Nitrile was 11%. We had the same material subjected to a cyclic test where the materials were cooled -20°F then heated to 180°F in 30 minutes, held at 180°F for 8 hours, cooled to -20°F in 60 minutes, held at -20°F for 14 hours 30 minutes for 144 hours. The compression set for the HNBR became 35% and the Nitrile became 17%. This additional cyclic compression set explained some of our seal failures in mobile equipment.

Paul, I like that first point you made about how all hydraulic seals will fail at some point. A mistake that people might make is forgetting that. It sounds like a no-brainer but I wouldn’t be amazed if people overlook that.