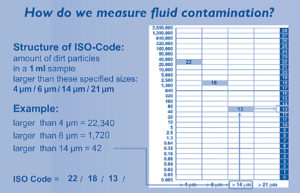

The objective of the ISO 4406:1999 is to classify particulate contaminants in hydraulic fluids. Particle counts are determined cumulatively, i.e. > 4 μm, > 6 μm and > 14 μm, and coded for easy comparison. Matt Brown Product Manager Filter Systems at Schroeder Industries gives the following table as an example. “This explains how the ISO code is determined for a particular fluid sample,” he said.

“Each difference in code, e.g. the 22 in example above increased to 23, would mean that the number of 4 Micron, and larger particulates would be doubled,” he said. “On the other hand, if the code goes down by one, the amount of particulates in a particular size range would be cut in half.”

Brown explained that the normal ISO code has three numbers that are declining in value from left to right, covering the 4, 6, 14 Micron and larger size particulates. “This is to be expected since the code to the right excludes smaller particulate sizes that are covered in the code on the left (higher particulate counts in the left code).”

Examples for ISO codes:

New hydraulic fluid delivered in a barrel: up to 23/21/18

New hydraulic fluid delivered in a Mini-Container (Tote): Up to 17/15/13

Fluid for hydraulic system with Servo valves and up to 3,000 psi pressure: 16/14/11

Fluid for hydraulic system with Cylinders, Vane Motors and/or Gear Motors and up to 3,000 psi pressure: 19/17/14

Fluid for hydraulic system with Cylinders, Vane Motors and/or Gear Motors and under 2,000 psi pressure: 20/18/15

As noted at the beginning of this tutorial, the objective of the ISO 4406:1999 is to classify particulate contaminants in hydraulic fluids. ISO-code charts provide easy comparison and classification of all types of particulate contaminants in hydraulic fluids. Of course, now that you have found them and classified them, the next step is to eliminate them. That is the province of your system cleanliness routine and your filtration system.

By Joyce Laird

Leave a Reply