By Donald Krause, Industry Consultant, Ohio Fabricators Company

Exploring the basics of spin-on filters: design and functionality

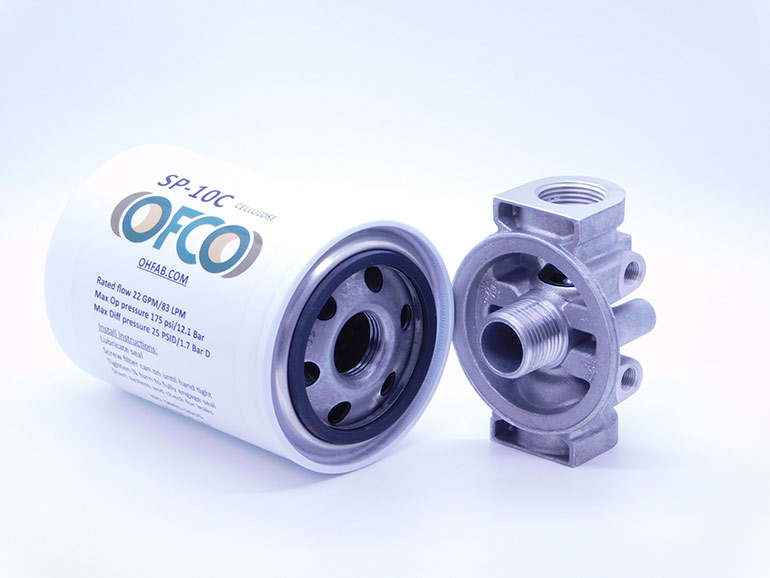

Spin-on filters have cemented their position as a cornerstone of liquid filtration and tank breather applications, thanks to their unique design and operational efficiencies. These filters consist of a self-contained housing and filter element assembly, which facilitates straightforward installation and replacement. This design not only enhances the filtration capacity but also significantly reduces maintenance time and costs. Predominantly used in hydraulic systems, lubrication oil systems, and fuel supply lines, spin-on filters excel at removing particulates and contaminants, thereby safeguarding critical system components and extending their service life. The widespread adoption of spin-on filters across various industries underscores their effectiveness in improving system cleanliness and reliability.

Key advantages

Spin-on filters provide operational efficiency, streamlined servicing processes, and a substantial decrease in maintenance expenditure, especially in environments fraught with contamination or presenting challenging operational conditions. Their efficiency stems from their advanced filtration capabilities, designed to meticulously purge particulate matter, thereby safeguarding hydraulic systems against potential pollutants. This prolongs equipment life and optimizes performance. Further, the ease of service associated with these filters — owing to their spin-on design — allows for quick, mess-free replacement, markedly reducing downtime. Lastly, the use of spin-on filters in adverse settings diminishes the frequency and necessity for complex maintenance interventions, leading to significant reduction in operational expenses.

Applications and benefits

Spin-on filters have carved a niche in diverse sectors, showcasing their adaptability from fluid conditioning systems to the rigorous demands of mobile and agricultural machinery. Their design caters to a broad spectrum of applications, ensuring that hydraulic systems, engines, and lubrication processes are free from contaminants. By integrating spin-on filters, businesses can safeguard their machinery against the detrimental effects of contamination, thereby optimizing performance and prolonging equipment lifespan.

General applications of spin-ons include the following:

- Fluid conditioning systems

- Drainage lines

- Transfer of fluids

- Hydrostatic loading pumps

- Power transmissions

- Closed-loop systems

- Mobile equipment (cement trucks, mobile cranes, waste management trucks, tankers, etc.)

- Agricultural equipment

- Power packs

- Earth moving equipment

- and many more applications

Any machine or equipment that uses hydraulic fluid can be an application for spin-on filters, as they offer several key benefits, including:

- Compact design and quality

- Easy to install

- Quick replacement

- No leaks during the maintenance operations, as oil is contained inside

- Made with oxidation resistant materials (aluminum heads)

- Optimal performance in any operational and environmental context

- As an additional usage for removing water from hydraulic fluid flowing through the system

- As a reservoir breather

Spin-on filters are the pinnacle of filtration technology, merging ease of maintenance with unparalleled efficiency. Their robust design, tailored to withstand diverse operational demands, positions them as the optimal choice for safeguarding power machinery and equipment.

For a more detailed review of spin-on filter use, visit ohfab.com.

Leave a Reply