The concept of Industry 4.0 or Industrial Internet of Things is still new and spreading in major industries with significant investment programs to improve performance, ensure competitiveness and increase value. It is a process that also is revolutionizing traditional maintenance towards smart predictive maintenance, allowing system maintainers to perform services just in time. Real-time machine status information, through remote monitoring and data expertise, significantly increases the availability of equipment, reduces downtime and extends the life of the machine, fluids, and components. Predictive maintenance is thereby a tool to also change business models and offer new after-sales services. It additionally enables manufacturers to offer their machines as a service.

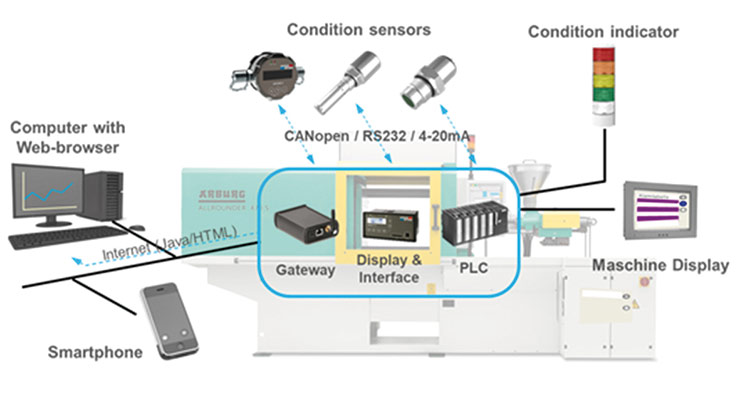

Argo-Hytos has developed online monitoring solutions for hydraulic fluids. These intelligent measurement systems use smart algorithms to monitor the aging of lubricants and the wear of hydraulic components. Argo-Hytos measurement systems detect problems at an early stage, before they cause further damage or downtime.

The smart predictive models are based on machine-specific learning, allowing the evaluation of time remaining before failure. This allows system maintainers to plan maintenance accordingly.

Argo-Hytos measurement solutions have proven their benefit in a wide range of applications, from remote monitoring of mobile equipment (e.g. agricultural, construction, material handling), to power generation and distribution (e.g. wind turbines, gas turbines, water power, gearboxes, fuel storage and transport, and transformers), machines (e.g. injection molding, presses, welding, grinding) and many more.

ARGO-HYTOS

argo-hytos.com

Leave a Reply