Machine manufacturers increasingly demand both functional integration within hydraulic systems and, of course, lower costs. Add to that, today’s engineers expect almost unlimited freedom when creating new designs. As a result, plastics have become an increasingly important material for constructing hydraulic tanks, according to engineers at ARGO-HYTOS.

Machine manufacturers increasingly demand both functional integration within hydraulic systems and, of course, lower costs. Add to that, today’s engineers expect almost unlimited freedom when creating new designs. As a result, plastics have become an increasingly important material for constructing hydraulic tanks, according to engineers at ARGO-HYTOS.

The company’s new injection-molded tanks reportedly offer numerous advantages over competing options. For instance, welded-steel tanks are costly if they entail complex geometries, and the price only gets worse if additional hydraulic capabilities are required as part of the tank. Rotationally molded and blow-molded plastic tanks typically have poor temperature and chemical resistance (particularly with polypropylene and polyethylene constructions), average to poor pressure resistance, can be difficult to clean and integrating functions can be difficult.

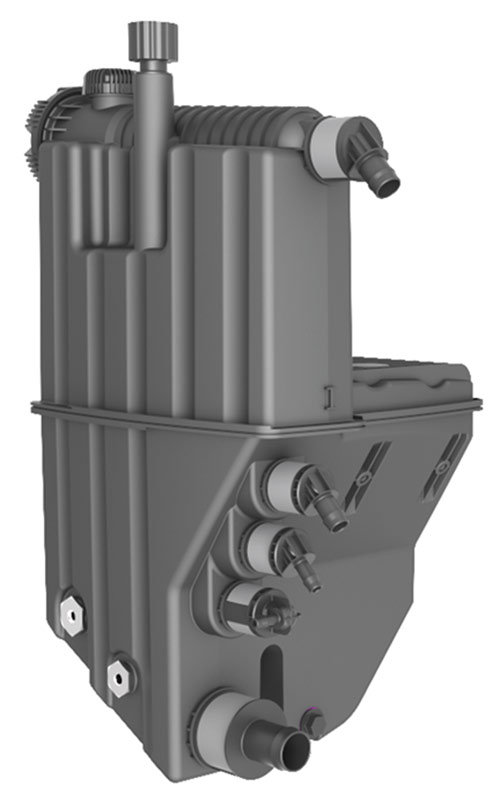

ARGO-HYTOS tanks, on the other hand, are made of polyamide and enjoy high mechanical strength and thermal stability. They offer good pressure and chemical resistance, permit complex external geometries and are easy to clean. The units are generally suited for small to medium tank volumes.

A major benefit is that the tanks allow relatively easy integration of several hydraulic functions into one system, without additional costs. Among components that can be integrated into the tanks include the filter housing, filling strainer, oil-level indicator, venting filter with rollover protection valve, quick-connect ports, sensor connections, oil drain plug, and baffles. As a result, machine builders no longer need to source, integrate and mount a lot of individual components. Relying on a single, complete module simplifies installation and results in substantial cost savings.

The use of injection molding lets ARGO-HYTOS create complex tank geometries with low manufacturing costs. It also gives wide design freedom, so engineers can optimally use the scarce available space on equipment. Various types of tanks are used in many mobile-hydraulic applications.

ARGO-HYTOS

argo-hytos.com

Leave a Reply