By Josh Cosford, Contributing Editor

Particle contamination is the proverbial lord of the contamination cartel. Particles get all the attention in this world, and rightfully so. Particle contamination-related failures likely outpace water, varnish and heat combined (yes, heat is a form of contamination). It would come as no surprise, then, that the primary driver of oil analysis programs is to measure and control particle contamination, so let’s discuss what that looks like from a practical perspective in this third installment of the Oil Analysis Series.

The most challenging part of a particle contamination test is probably collecting the sample. Your focus lies in two areas here — collecting a systemically relevant sample and collecting in such a way as to avoid adulteration and artificially skewing the result. We must consider how the place from which we take our sample is indicative of what the whole system experiences. Additionally, any contamination added from a dirty collection method must be avoided.

Image courtesy Rocky Mountain Filtration Solutions

The best sample location is an active stream returning from the circuit before it can be filtered, such as the return line. A teed-in ball valve with a microbore hose makes a perfect solution for filling sample bottles. While the system is running and warm, the mechanic should first purge the hose and discard a small amount of oil to ensure any residual contamination inside the hose is removed. The mechanic then fills the bottle as required and immediately seals the lid.

Be sure to write down all the relevant information for the lab to help track results for individual machines, such as oil viscosity, reservoir volume, machine number and description, date of sampling and any other important information. Many labs will provide serial number decals to place on the sample bottle that match the paperwork to reduce mix-ups.

Once ready, you can deliver or ship the sample bottle to the lab, where they will analyze the sample to measure the number of particles and then express them in one milliliter of fluid. ISO 4406 is the standard by which we express the number of 4, 6 and 14-micron particle sizes determined to wreak havoc on pumps, valves and actuators. Any smaller and their damage would be minimal, while any larger and they’d be too large to get stuck anywhere important.

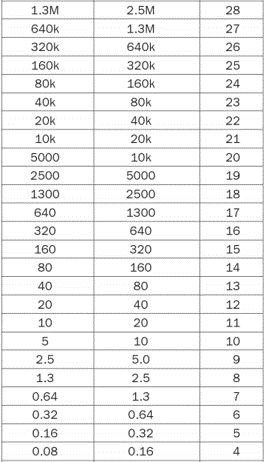

The oil analysis report will show you a single number used to express the range of particles for each of the three sizes since measurement technology is not at the sophistication to measure each and every single particle. Figure 1 shows the code range in the left column and then the range in the left and middle columns. For example, when the 6-micron particles range from 640 to 1300 counted in one milliliter of fluid, we express it simply as 17.

Going further, let’s say the lab comes back with 18/15/13 (which isn’t terrible) on your report; then you know you’re dealing with 1300-2500 4µm particles, 160-320 6µm particles and 40-60 14µm particles. Some labs will also go deeper and tell you other sizes of particles found in the oil, such as 25 µm or 100 µm and larger. If you have any 100-micron particles in your oil, it’s likely your filter is in bypass.

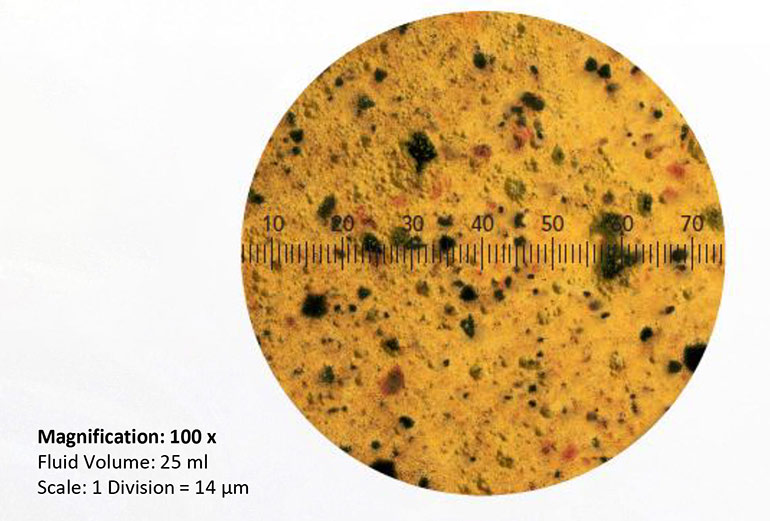

Besides ISO 4406, the lab may also offer particle tests to help you understand your oil’s health. The patch test is a common visualization tool that looks for the presence of contaminants in the oil by applying the sample to a paper patch or membrane where the particles rest. The sample is viewed in a microscope, and a snapshot is observed and interpreted for things like wear particles or obvious forms of contamination.

Finally, the lab will usually tell you the material composition of the particles using spectrometry, which helps you identify specific alloys that are wearing, such as iron, copper, nickel, chrome and bronze. Should one of these represent an excessive count, you could trace it back to a part using this material, such as a bronze bushing or iron valve spool.

Just as with all hydraulic analysis programs, it’s important to schedule your oil sample analyses once or twice a year consistently to graph trends in oil quality and particle size and type. Should any anomalies appear, you can be sure to keep an eye on possibly nefarious trends.

Leave a Reply