A pump is the heart of a hydraulic system. When the pump fails, the entire system is down until the pump is operational again. This poses a serious threat to any operation relying on hydraulic systems for productivity. Recently, a hydraulic valve manufacturer was losing 25 pumps a year on their centralized hydraulic system at a cost of $2,440 each. That’s only the pump cost—when you account for maintenance resources, lost oil and lost production, each failure costs approximately $25,320.

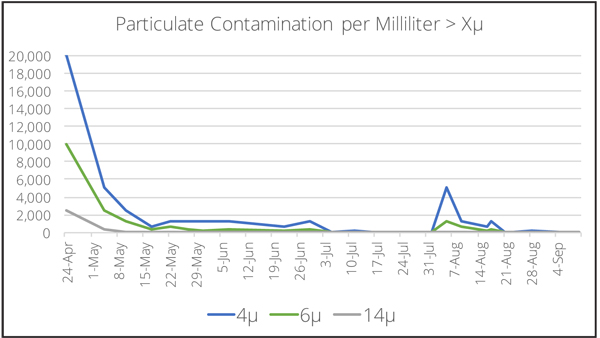

System analysis showed that fluid contamination was out of control with an ISO Fluid Cleanliness Code of 22/21/19. That translates to a minimum of:

- 20,000 particles per ml > 4µ[c]

- 10,000 particles per ml > 6µ[c]

- 2,500 particles per ml > 14µ[c]

To reduce these failures, the manufacturer set an ISO code limit of 17/15/13 and turned to Hy-Pro Filtration for help. While surveying the system, Hy-Pro noticed and addressed three factors contributing to these problems.

The hydraulic tanks were open to the environment. This allows the dirt and dust in the environment to find its way into the fluid. These tanks were sealed to prevent further contamination ingression from the environment.

The hydraulic tanks were open to the environment. This allows the dirt and dust in the environment to find its way into the fluid. These tanks were sealed to prevent further contamination ingression from the environment.

The tanks lacked breathers. Hydraulic tanks should be sealed from the environment but there must be a way to allow air exchange to occur between the tank and environment as fluid enters and evacuates the tank. Breathers were added to the tanks to allow this exchange to occur in a controlled manner by removing contamination from the air entering the reservoir before it reaches the fluid.

A Brand-X 12-µ filter element installed in the offline filtration system was upgraded to a 6-µ Hy-Pro DFE Rated G8 Dualglass element as more efficient filtration would be necessary to drop the ISO code below the 17/15/13 limit.

Fluid analysis samples were taken over the following 140 days to verify the condition of the fluid. The final sample returned an ISO Fluid Cleanliness Code of 12/11/7, even better than the manufacturer had planned for. That translates to a maximum of:

- 40 particles per ml > 4µ[c]

- 20 particles per ml > 6µ[c]

- 1 particle per ml > 14µ[c]

Simple changes like the three mentioned above almost completely eliminated pump failures due to fluid contamination, saving approximately $633,000 annually, with a 99.8% reduction in particulate contamination within the fluid.

Hy-Pro Filtration

hyprofiltration.com

Leave a Reply