Any hydraulic system user must take contamination and cavitation prevention seriously, as these two activities can severely damage components and machinery.

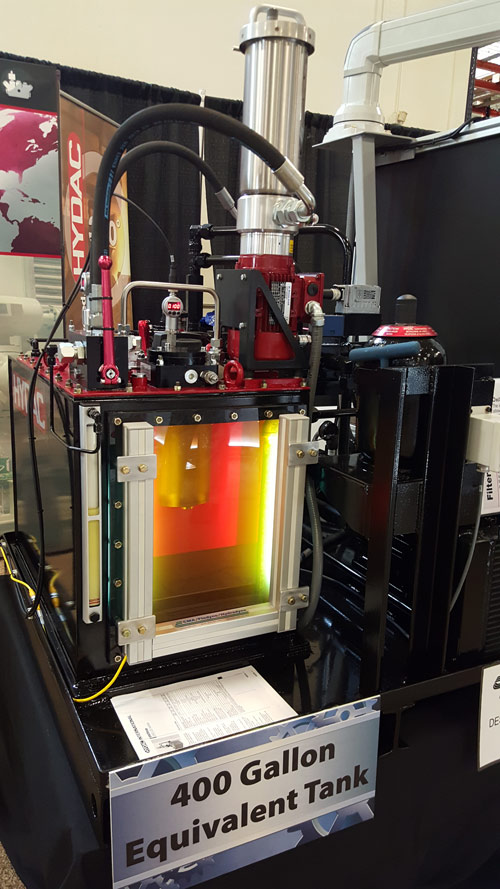

One such answer to these problems is HYDAC’s OXiStop LID series, a tank solution for hydraulic systems with an integrated, hydraulically driven degassing and dewatering unit. It is designed to be installed in extremely dusty or humid environments. It easily removes water and air from a system, said Daniel Zoller, Group Product Manager Filter Systems at HYDAC/Schroeder Industries.

Zoller added that the OxiStop eliminates cavitation. This is because the sealed system prevents dirt and air from being pulled in from the atmosphere. An integrated membrane prevents direct contact with the ambient air.

By reducing the tank size and removing air, you can reduce oil volume by a factor of 10. Fluid flows in and out of the tank as needed. For example, a 30 liter (a tank of approximately 40-45 gal) unit can replace a 400 gal typical tank.

Users select the tank for the differential operating volume actually needed, which reduces its size. They are available in three sizes of up to a differential volume of 30, 45 and 70 liters. Custom designs are also available.

A kidney loop system continuously runs and provides flow to the system. It features a top-loaded filter rated for 2µm.

The pump flow rate is not important for the tank design. In addition, the membrane helps the fluid stay “vacuum packed.” The pump and tank operation prevents settling time. And because you can reduce the air in the system, you can increase the bulk modulus of the oil, Zoller said, which makes it stiffer. This, in turn, increases energy efficiency while reducing costs of fluid required.

Users can choose to equip the OXiStop with an optional return line filter, water/oil cooler as well as with the AquaSensor AS and the ContaminationSensor CS.

The system also increases oil service life, reduces oxygen content by 80% and reduces contamination ingression (solid, liquid, gaseous). An added bonus is reduced noise due to reduced cavitation.

HYDAC

www.hydac.com

Leave a Reply