The Filtration Division of Eaton has expanded its product line with the launch of three high-performance filter series: the DUA, LWF, and DNR. The new filters are engineered to provide hgh durability, efficiency, and reliability, making them suitable for demanding applications such as power generation, manufacturing, marine operations, and more.

“As pressures mount to safeguard critical processes and minimize downtime, having a dependable filtration solution that can operate uninterrupted is essential,” said Simone Ortner, Hydraulic Filtration Engineering and Product Manager at Eaton’s Filtration Division. “Our new filters are tailored to meet the practical needs of industries facing challenging conditions and tight operational schedules.”

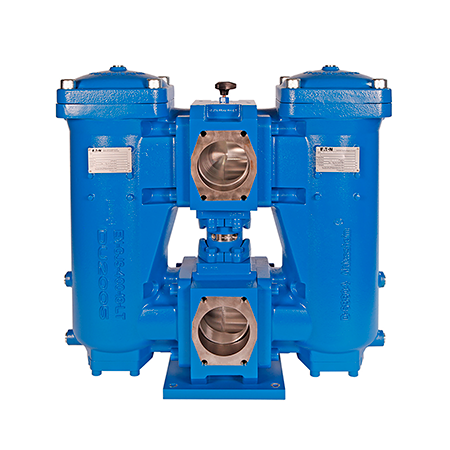

DUA duplex pressure filters in ASME design — For nonstop, high-demand applications, Eaton’s DUA duplex filters build on the already available DU filter series, meeting ASME, PED and EN 13445 requirements without additional accessories. The DUA series also keeps filtration running smoothly by allowing the operator to divert the filtration flow from one side to the other. A clogging indicator can be assembled directly to the switch gear housing without any piping. Handling operating pressures up to 320 psi (22 bar) and flow rates of 1,056 gpm (4,000 lpm), DUA filters are best for power plants, manufacturing facilities, and marine systems. They are available in sizes 2005, 3005, and 4005.

LWF in-line pressure filter series — Eaton’s LWF in-line pressure filters are built for flexibility across various applications. They can be installed on suction, pressure, or return lines and are equipped with the pleated 01.E1501 filter element that boosts dirt-holding capacity. The filter element series features various filter media types and grades of filter finesse. The LWF series handles operating pressure up to 232 psi (16 bar), flow rates between 396 gpm (1,500 lpm) to 1,585 gpm (6,000 lpm) and is available in stainless steel (ELWF) as well as in ASME design (LWFA, ELWFA).

DNR duplex pressure filter series — Eaton’s DNR duplex pressure filters are suitable for systems that need to withstand operating pressures up to 232 psi (16 bar). Designed with a three-way changeover valve, these filters allow for element changes without halting filtration and are well suited for lubrication of gear boxes and turbines. The carbon steel housing can hold Eaton’s 01.NR630 and 01.NR1000 filter elements, giving users flexibility across various setups and dependable performance under a range of conditions. The previously available DNR filter series is now available in sizes 5265 and 7265, and also includes a stainless-steel option (EDNR) as well as an ASME design (DNRA, EDNRA).

“By combining advanced design with different housing material options, these filters address the increasingly complex challenges of modern hydraulic and lubrication oil systems, ensuring optimal performance and peace of mind for their operators,” adds Ortner.

Eaton

eaton.com/filtration

Leave a Reply