Tan Delta Systems, a manufacturer of real-time oil quality monitoring sensors and systems, is leading the way within the manufacturing and lubrication sector with the launch of SENSE-2. The new oil condition monitoring kit provides real-time data about machine oil quality to optimize maintenance and reduce operating costs.

The SENSE-2 is plug-and-play and accurately identifies when oil reaches the end of its life, superseding traditional time-based maintenance schedules which can result in oil being discarded prematurely — with the potential of wasting up to 50% of its useful life.

For the manufacturing and lubrication industries, SENSE-2’s ability to extend maintenance intervals by monitoring equipment condition in real-time, results in answering the actual equipment needs rather than maintenance being driven by time-based scheduling. This, in conjunction with reducing the business’s carbon footprint, will help support sustainability goals by reducing oil consumption by approximately 30% per year, as well as reducing parts consumption and extending equipment life.

Chris Greenwood, CEO at Tan Delta Systems said, “Our SENSE-2 real-time monitoring utilizes our world-leading sensor technology and associated analytics to detect any issues before the damage occurs, identifying subtle changes in equipment condition early. It can be fitted easily and efficiently to any existing equipment in any application and is configurable to any oil type.

“Although oil analysis is not new, traditional lab sampling is expensive and impractical with other sensors focusing on specific parameters while missing others. Our system ensures the industry has access to superior quality information in an easy-to-use format, preventing excessive wear of components resulting in increased productivity and reduced machine downtime and maintenance costs.”

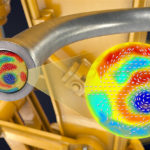

The real-time aspect of the system is what sets it apart, using unique active molecular-level analysis to detect all changes in oil condition and any contamination. The Tan Delta sensor works by providing a full-spectrum holistic (FSH) oil quality analysis, which continuously monitors the ratio of two key measurements, capacitance and conductance, to provide real-time insight.

This molecular analysis taking place every few seconds enables accurate tracking of oil degradation as well as detecting contamination and early signs of internal equipment problems. This allows for precise predictions of maintenance points crucially optimizing maintenance scheduling, and reducing costs and downtime.

The OQSx-G2 oil quality sensor within the SENSE-2 kit is also available as a Mobile Oil Tester (MOT) kit, created with workshops and mobile maintenance teams in mind. Any oil from any equipment can be sampled and tested simply and easily on-site in seconds. The sensor is used in conjunction with the MOT software, which operates on any Windows-based laptop, tablet or PC. Users simply install the MOT app, connect it to the sensor, collect the sample in one of the bottles provided and follow the steps in the software to test the sample.

Tan Delta

www.tandeltasystems.com

Leave a Reply